¶ Introduction

The chapter gives detailed insights into the components and processes of Sumo models. This information helps the user to understand the interactions between components, indicates the model logic and consideration behind the mathematical description.

¶ Components in Sumo models

There are five symbols that distinguish the types of components, also referred to as state variables (SVs):

- soluble (S),

- colloidal (C),

- particulate (X),

- gaseous (G),

- and enthalpy (H).

The soluble SVs are transported through water, and colloidal SVs and particulate SV become part of the sludge which then can be separated from water through the settling process.

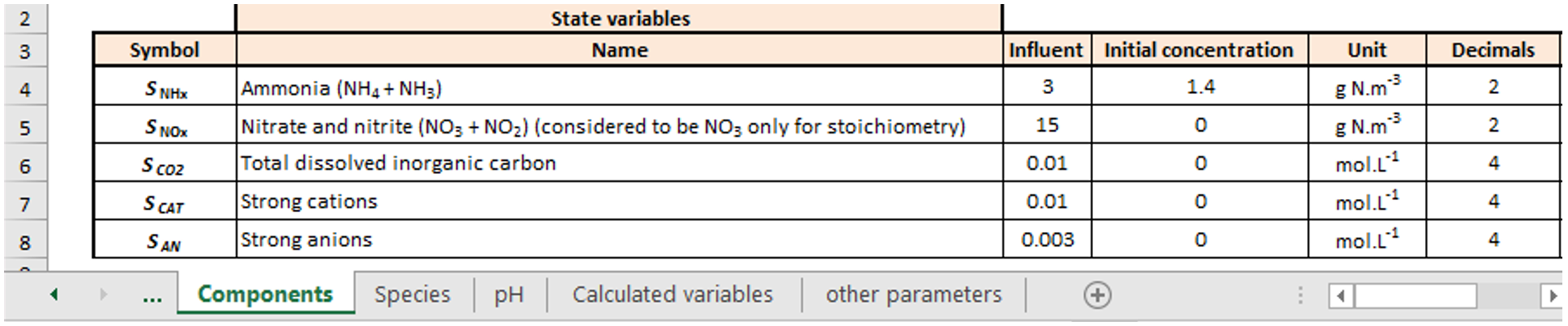

| Components | ||||

|---|---|---|---|---|

| Symbol | Name | Model | Definition | Unit |

| SVFA | Volatile fatty acids (VFA) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A fermented product representing a combination of acetate and other volatile fatty acids produced in an anaerobic environment from SB. It is available for biological removal by OHOs, CASTOs (PAOs, GAOs), and AMETOs and chemical removal during HFO reduction. | g COD.m-3 |

| SB | Readily biodegradable substrate (non-VFA) | Mini_Sumo, Sumo1, Sumo2, Sumo2S, Sumo4N | Non-VFA organic material that can be fermented to VFA, it represents a group of readily biodegradable organic material present in wastewater. | g COD.m-3 |

| SB,mono | Readily biodegradable substrate as monomers (non-VFA) | Sumo2C | Small molecular weight substrate mainly consumed by AHOs in 1st stage of high-rate process. | g COD.m-3 |

| SB,poly | Readily biodegradable substrate as polymers | Sumo2C | Readily biodegradable substrate that is not degraded in 1st stage of a high-rate process. Consumed by OHOs in 2nd stage. | g COD.m-3 |

| SMEOL | Methanol (MEOL) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A methyl alcohol or the simplest alcohol. A commonly used external carbon source for denitrification. | g COD.m-3 |

| CB | Colloidal biodegradable substrate | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A biodegradable organic component, flocculates to form XB. Analytically can be approximated by flocculation or filtration (larger than 0.1 micron but smaller than 1.2 micron) | g COD.m-3 |

| XB | Slowly biodegradable substrate | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N |

High molecular weight particulates that are hydrolyzed by extracellular enzymes to release SB. They are introduced directly from the influent. In Mini_Sumo they are also released during the bacterial decay process in death-regeneration concept models. |

g COD.m-3 |

| XB,e | Slowly biodegradable substrate from biomass decay | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N |

High molecular weight particulates that are hydrolyzed by extracellular enzymes to release SB, with a lower rate than XB. Tehy are released during the bacterial decay process in death-regeneration concept models.

|

g COD.m-3 |

| SU | Soluble unbiodegradable organics | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A soluble organic material that is not degraded biologically or chemically in wastewater and leaves in the effluent. Typically, measured by performing a flocculated filtration test on the effluent of a nitrifying plant. It also has a nitrogen and phosphorus content. There is only one process, the Thermal Hydrolysis Process, which generates SU from XU in the model. | g COD.m-3 |

| CU | Colloidal unbiodegradable organics | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A non-biodegradable organic material, flocculates to form XU and leaves the plant in the WAS or cake. Analytically can be approximated by flocculation or filtration (larger than 0.1 micron but smaller than 1.2 micron) | g COD.m-3 |

| XU | Particulate unbiodegradable organics | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A non-biodegradable organic material that is larger than 1.2 micron. It is not hydrolysed and remains untransformed due to biological and chemical reactions. The thermal hydrolysis process model is the only unit that converts a portion of XU to SU. | g COD.m-3 |

| XSTO | Storage product of AHOs | Sumo2C | An internal cell storage organic material stored by AHOs in low SRT systems using SB,mono and SVFA. Its production doesn’t involve any energy and growth. | g COD.m-3 |

| XPHA,PAO | Polyhydroxyalkanoates (PHA) stored by PAOs | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Poly-hydroxy alkanoates considered as an internal organic cellular storage product of CASTOs (PAOs). The composition of alkanoates is represented as poly-β-hydroxybutyrate. | g COD.m-3 |

| XPHA,GAO | Polyhydroxyalkanoates (PHA) stored by GAOs | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Poly-hydroxy alkanoates considered as an internal organic cellular storage product of CASTOs (GAOs). The composition of alkanoates is represented as poly-β-hydroxybutyrate. | g COD.m-3 |

| XE | Endogenous decay products | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | An organic material released during cell lysis under aerobic and anoxic environment, it has an extremely slow conversion rate of 0.07 per day and it converts to XB while releasing SNHx and SPO4. The XE builds in a system with increasing SRT. | g COD.m-3 |

| XE,ana | Anaerobic endogenous decay products | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | An organic material released on cell lysis under anaerobic environment and hydrolysed in aerobic environment to release SB, SNHx, and SPO4. This component is responsible for the additional VS destruction observed in a post aerobic digestion process. | g COD.m-3 |

| XOHO | Ordinary heterotrophic organisms (OHO) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Generalist facultative ordinary hetrotrophic organisms that consume different soluble biodegradable organics including SB, SVFA, and XMEOL and can perform biological removal under aerobic, anoxic, and anaerobic environments. They are also responsible for hydrolysis of the particulates. In MiniSumo and Sumo1, they perform one step denitrification, meaning from SNOx to SN2. In other models they follow two steps, SNO3 reduction to SNO2, and SNO2 reduction to SN2. | g COD.m-3 |

| XCASTO | Carbon storing organisms (CASTO) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A special group of carbon storing heterotrophic organisms representing a combination of both PAOs and GAOs. The process conditions dictate the ratio of PAO to GAO achieved in the process model. They are responsible for taking part in the EBPR process. They store PHA and/or GLY during the anaerobic conditions, and consume stored carbon during anoxic and aerobic environments to generate polyphosphate (XPP). In Sumo1, they perform one step denitrification, meaning from SNOx to SN2. Is other models they follow two steps, SNO3 reduction to SNO2, and SNO2 reduction to SN2. | g COD.m-3 |

| XMEOLO | Anoxic methanol utilizers (MEOLO) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Specialist heterotrophic organisms responsible for removal of XMEOL. Only found in systems with methanol addition and compete with OHOs during denitrification process. In Sumo1, they perform one step denitrification, meaning from SNOx to SN2. Is other models they follow two steps, SNO3 reduction to SNO2, and SNO2 reduction to SN2. | g COD.m-3 |

| XAHO | Carbon adsorption heterotroph organisms (AHO) | Sumo2C | Heterotrophic organisms storing readily biodegradable small molecular weight components represented as SB,mono and volatile fatty acids (SVFA) into XSTO. The growth rate of AHOs is higher than that of the OHOs and outgrow them in a short SRT system of <2 days. They only carry out aerobic consumption of the XSTO and are expected to be seeded from the influent. | g COD.m-3 |

| XNITO | Aerobic nitrifying organisms (NITO) | Mini_Sumo, Sumo1 | Obligate aerobic autotrophic organism responsible for complete nitrification, from SNHx to SNOx. It represents a combination of AOBs and NOBs for simplification in the referred models. | g COD.m-3 |

| XAOB | Aerobic ammonia oxidizers (AOB) | Sumo2, Sumo2C, Sumo2S, Sumo4N | Obligate aerobic autotrophic organism responsible for the first step in nitrification, from SNHx to SNO2. | g COD.m-3 |

| XNOB | Nitrite oxidizers (NOB) | Sumo2, Sumo2C, Sumo2S, Sumo4N | Obligate aerobic autotrophic organism responsible for the second step in nitrification, from SNO2 to SNO3. | g COD.m-3 |

| XAMX | Anammox organisms (AMX) | Sumo2, Sumo2C, Sumo2S, Sumo4N | A chemoautotrophic anaerobic bacteria that oxidizes ammonium with nitrite as the electron acceptor and with CO2 as the main carbon source. They are slow growers and have a long doubling time. | g COD.m-3 |

| XAMETO | Acidoclastic methanogens (AMETO) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Anaerobic archea that consume SVFA to produce SCH4 and SCO2 as a metabolic by-product and don’t grow under aerobic conditions. | g COD.m-3 |

| XHMETO | Hydrogenotrophic methanogens (HMETO) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Anaerobic archea that consume SH2 and SCO2 to produce SCH4 as a metabolic by-product and don’t grow under aerobic conditions. | g COD.m-3 |

| XASRO | Acidoclastic sulfate-reducing organisms (ASRO) | Sumo2S | A group of bacteria and archaea that perform anaerobic respiration utilizing SSO4 and SVFA, reducing it to SH2S and generating SCO2. They compete with AMETOs for SVFA and negatively impact performance of a digester. | g COD.m-3 |

| XHSRO | Hydrogenotrophic sulfate-reducing organisms (HSRO) | Sumo2S | A group of bacteria and archaea that perform anaerobic respiration utilizing SSO4 and SH2, reducing it to SH2S. They compete with HMETOs for SH2 consumption and negatively impact performance of a digester. | g COD.m-3 |

| XSOO | Sulfur-oxidizing organisms (SOO) | Sumo2S | They oxidize SH2S in two steps under aerobic and anoxic environments, first from SH2S to XS (elemental sulfur) and second from XS to SSO4. | g COD.m-3 |

| XALGAE | Photosynthetic organisms (ALGAE) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A group of photosynthetic organisms which grow, assimilate nutrients, SCO2 and generate SO2 in the presence of light. They consume SO2 through respiration. | g COD.m-3 |

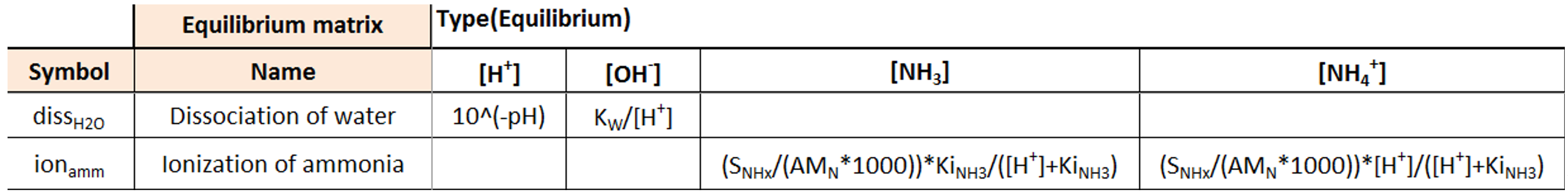

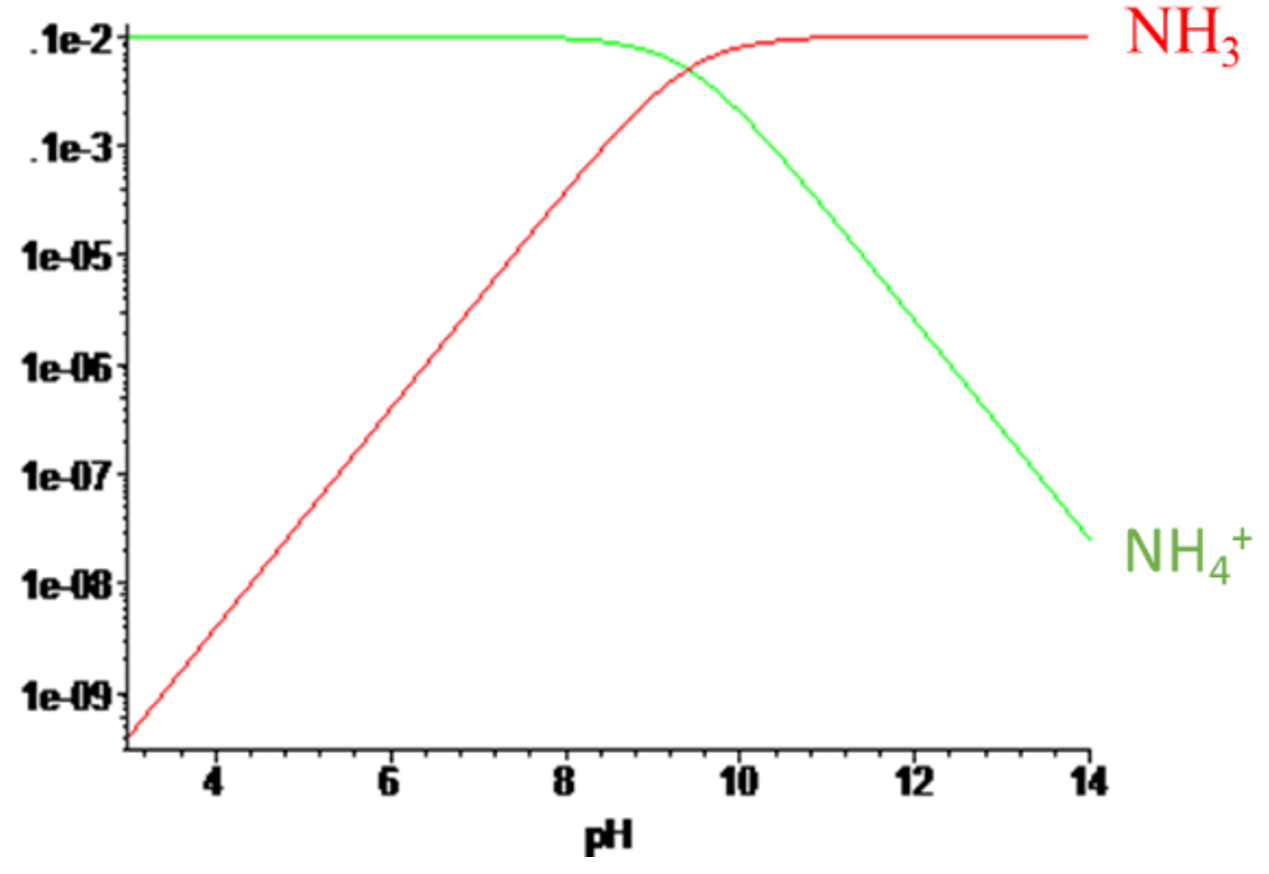

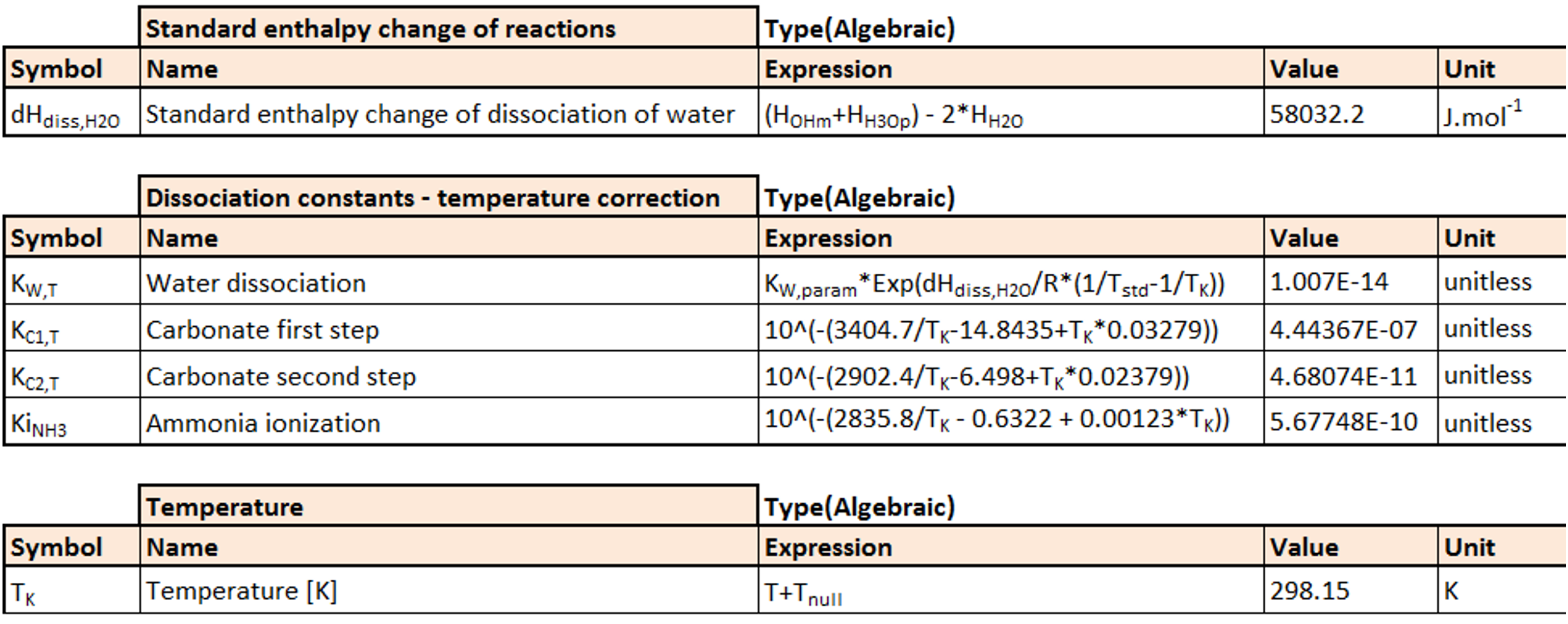

| SNHx | Total ammonia (NHx) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Total ammonia nitrogen is a sum of ammonium and free ammonia. An essential nutrient for the biokinetic growth reactions. | g N.m-3 |

| SNH2OH | Hydroxylamine (NH2OH) | Sumo4N | An intermediate product produced by AOB from SNHx. It is then oxidized to SNO under aerobic environments. It is also reduced to form SN2O under anoxic environments. | g N.m-3 |

| SNOx | Nitrate and nitrite (NOx) | Mini_Sumo, Sumo1 | A sum of nitrate and nitrite, and electron acceptor for anoxic reactions. In the referred Models it is considered nitrate for all COD conservation purposes. | g N.m-3 |

| SNO2 | Nitrite (NO2) | Sumo2, Sumo2C, Sumo2S, Sumo4N | A sum of nitrous acid and nitrate ion and electron acceptor for anoxic reactions. | g N.m-3 |

| SNO3 | Nitrate (NO3) | Sumo2, Sumo2C, Sumo2S, Sumo4N | An electron acceptor for anoxic reactions. | g N.m-3 |

| SNO,AOB | Nitric oxide of AOB (NO) | Sumo4N | Nitric oxide generated by AOBs from SNH2OH and either oxidized to SNO2 and reduced to SN2O. It is considered as an internal product. | g N.m-3 |

| SNO,OHO | Nitric oxide of OHO (NO) | Sumo4N | Nitric oxide generated by OHOs during SNO2 reduction. It is considered as an internal product. | g N.m-3 |

| SN2O | Nitrous oxide (N2O) | Sumo4N | Generated by OHOs from SNO,OHO and by AOBs from SNO,AOB. | g N.m-3 |

| SN2 | Dissolved nitrogen (N2) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Only nitrogenous product of denitrification except for in Sumo4N model and is subject to gas transfer. | g N.m-3 |

| SN,B | Soluble biodegradable organic N (from SB) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A nitrogen containing soluble organic material (urea, amino acids, amines, and others) that releases nitrogen as total ammonia on ammonification in wastewater treatment. In the model it doesn’t have COD associated. | g N.m-3 |

| XN,B | Particulate biodegradable organic N (from XB) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A nitrogen containing particulate organic material (proteins and others) that releases SN,B on hydrolysis in wastewater treatment. In the model it doesn’t have COD. | g N.m-3 |

| XN,U | Particulate unbiodegradable organic N | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A nitrogen containing particulate organic material that is not biologically or chemically degraded in the plant and leaves with the cake solids. The only process that degrades XN,U to SNHx is the thermal hydrolysis process. | g N.m-3 |

| SPO4 | Orthophosphate (PO4) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Soluble inorganic phosphorus, represents a combination of Phosphoric acid, Dihydrogen phosphate ion, Hydrogen phosphate ion, Phosphate ion. An essential nutrient for the biokinetic growth reactions. | g P.m-3 |

| XPP | Stored polyphosphate (PP) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Poly-phosphate considered as an internal inorganic cellular storage product of CASTOs (PAOs). The composition of XPP is (Ca0.1K0.1Mg0.35PO3)n. | g P.m-3 |

| SP,B | Soluble biodegradable organic P (from SB) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A phosphorus containing soluble organic material that releases phosphorus as SPO4 in wastewater treatment. In the model it doesn’t have COD. | g P.m-3 |

| XP,B | Particulate biodegradable organic P (from XB) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A phosphorus containing particulate organic material that releases SP,B on hydrolysis in wastewater treatment. In the model it doesn’t have COD. | g P.m-3 |

| XP,U | Particulate unbiodegradable organic P | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A phosphorus containing particulate organic material that is not biologically or chemically degraded in the plant and leaves with the cake solids. The only process that degrades XP,U to SPO4 is the process model of thermal hydrolysis process. | g P.m-3 |

| SO2 | Dissolved oxygen (O2) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Dissolved oxygen is major electron acceptor for aerobic system and is subjected to gas transfer. | g O2.m-3 |

| SCH4 | Dissolved methane (CH4) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Dissolved methane is the most reduced form of carbon and end product of methanogensis. They are subjected to gas transfer. | g COD.m-3 |

| SH2 | Dissolved hydrogen (H2) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Dissolved hydrogen is generated during fermentation and transformed to SCH4 during methanogensis. They are subjected to gas transfer. | g COD.m-3 |

| SALK | Alkalinity (ALK) | MiniSumo | Assumed to be bicarbonate and used for appropriate conversion of electric charges in the biokinetic reactions. | eq ALK.L-1 |

| SCO2 | Total inorganic carbon (CO2) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A sum of carbonic acid, bicarbonate ion, carbonate ion. It is end product of many biological reactions. As bicarbonate it is a substrate for nitrification and also consumed during methanogenesis. | g TIC.m-3 |

| XINORG | Inorganics in influent and biomass | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | It represents the inorganic inerts present in influent and the biomass (0.11 g TSS.g COD-1). It has a SNa, SCl, SCa and SMg content. | g TSS.m-3 |

| SCAT | Other strong cations (as Na+) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Represented as sodium and is an essential element for biomass. It participates in pH and precipitation reactions. | g Na.m-3 |

| SAN | Other strong anions (as Cl-) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Represented as chloride and is an essential element for biomass. It participates in pH and precipitation reactions. | g Cl.m-3 |

| SCa | Calcium | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | An essential element for biomass and XPP and participates in pH and precipitation reactions. | g Ca.m-3 |

| SMg | Magnesium | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | An essential element for biomass and XPP. It participates in pH and precipitation reactions. | g Mg.m-3 |

| SK | Potassium | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | An essential element for biomass and XPP. It participates in pH and precipitation reactions. | g K.m-3 |

| SH2S | Hydrogen sulfide (H2S) | Sumo2S | Dissolved hydrogen sulfide gas, its subjected to gas transfer, biological and chemical reactions. | g S.m-3 |

| SSO4 | Sulfate (SO4) | Sumo2S | An end product of SH2S oxidation. It participates in pH determination | g S.m-3 |

| XS | Particulate elemental sulfur (S) | Sumo2S | An intermediary product of partial SH2S oxidation. | g S.m-3 |

| XFeOH | Ferric hydroxide compounds (FeOH) | MiniSumo | Phosphorus-binding capacity of ferric hydroxides | g Fe.m-3 |

| XFeP | Ferric phosphate compounds (FeP) | MiniSumo | This component results from binding phosphorus to the XFeOH. | g Fe.m-3 |

| XAlOH | Aluminium hydroxide compounds (AlOH) | MiniSumo | It stands for phosphorus-binding capacity of possible Al hydroxides | g Al.m-3 |

| XAlP | Aluminium phosphate compounds (AlP) | MiniSumo | This component results from binding phosphorus to the XAlOH. | g Al.m-3 |

| SFe2 | Ferrous ion (Fe2) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Ferrous ion oxidized to ferric ion and then participates in XHFO formation. It precipiates SH2S to XFeS and SPO4 to XVivi under anaerobic environments. | g Fe.m-3 |

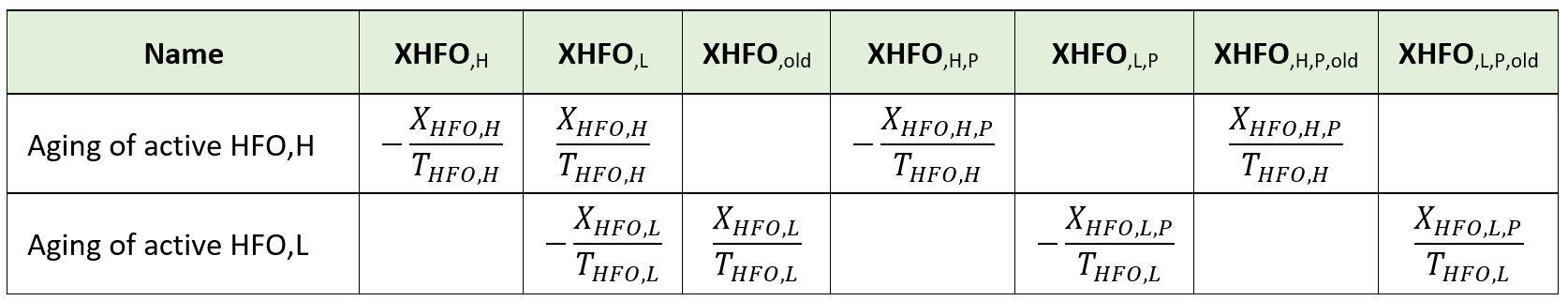

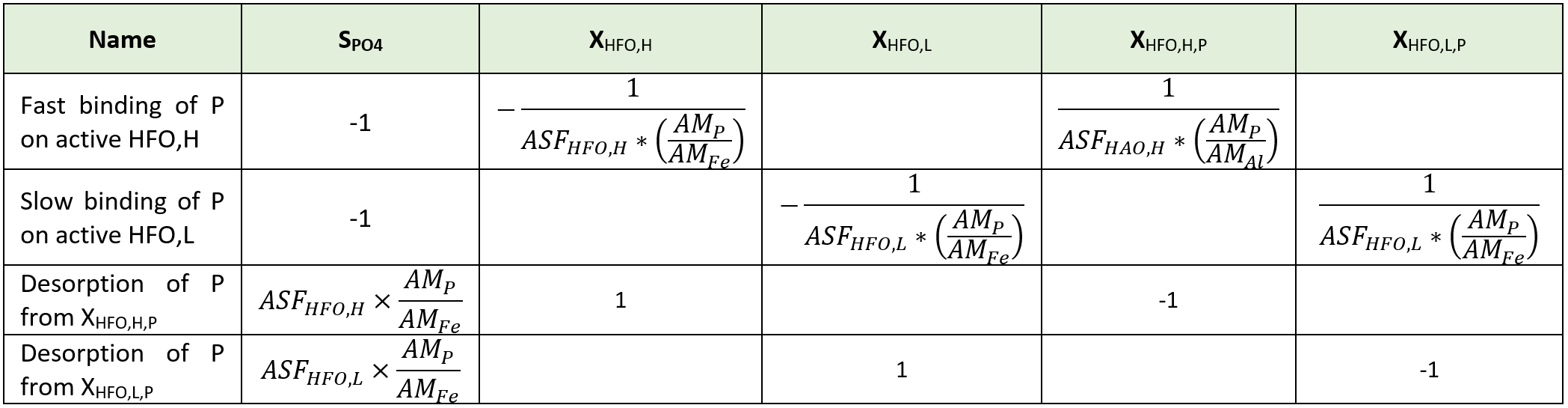

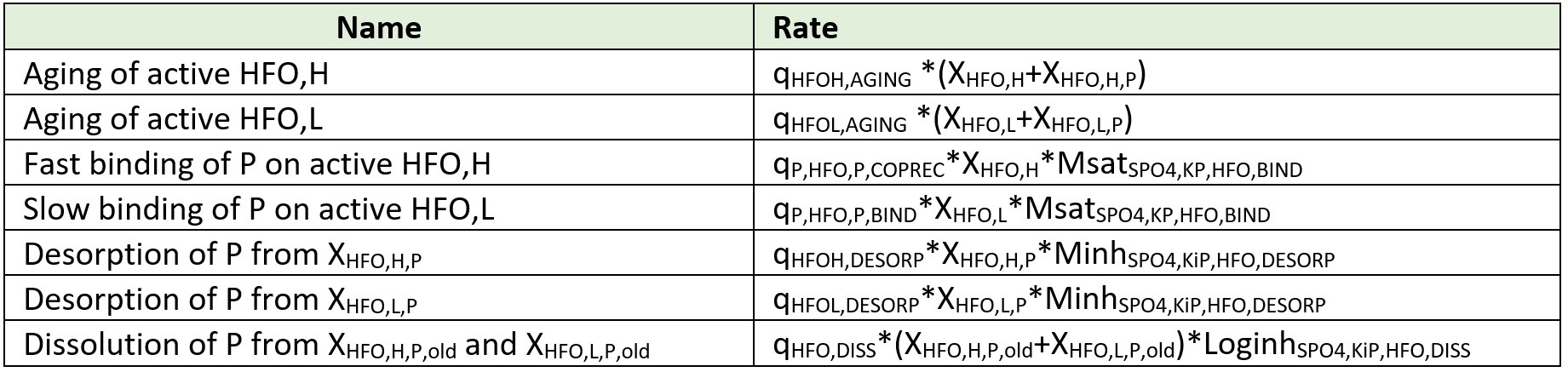

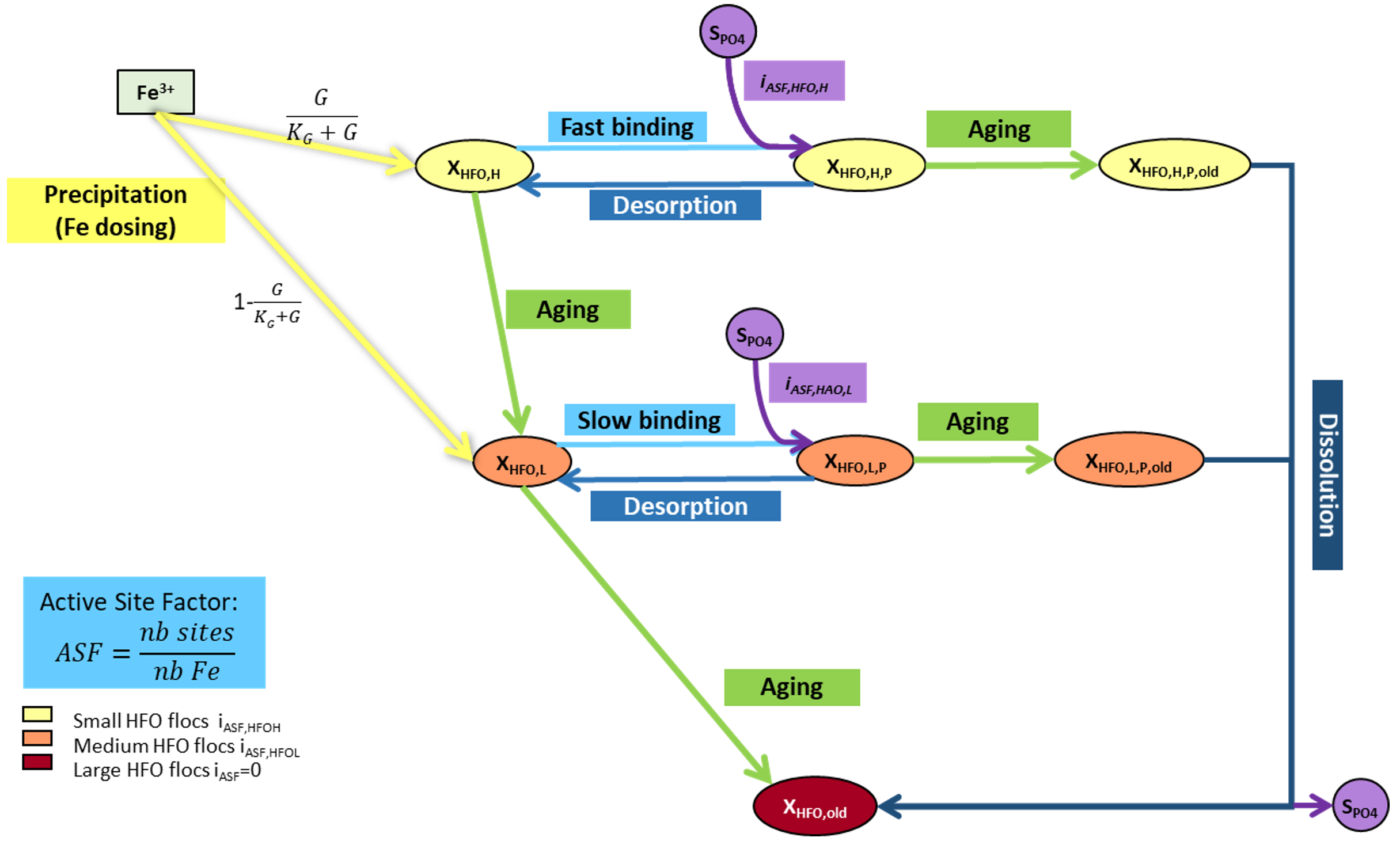

| XHFO,H | Active hydrous ferric oxide, high surface (HFO,H) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A ferric hydroxide with high surface area and high capacity to bind SPO4. Higher mixing condition results in more XHFO,H formation compared to XHFO,L. | g Fe.m-3 |

| XHFO,L | Active hydrous ferric oxide, low surface (HFO,L) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A ferric hydroxide with low surface area and low capacity to bind SPO4. Poor mixing condition results in more XHFO,L formation compared to XHFO,H. | g Fe.m-3 |

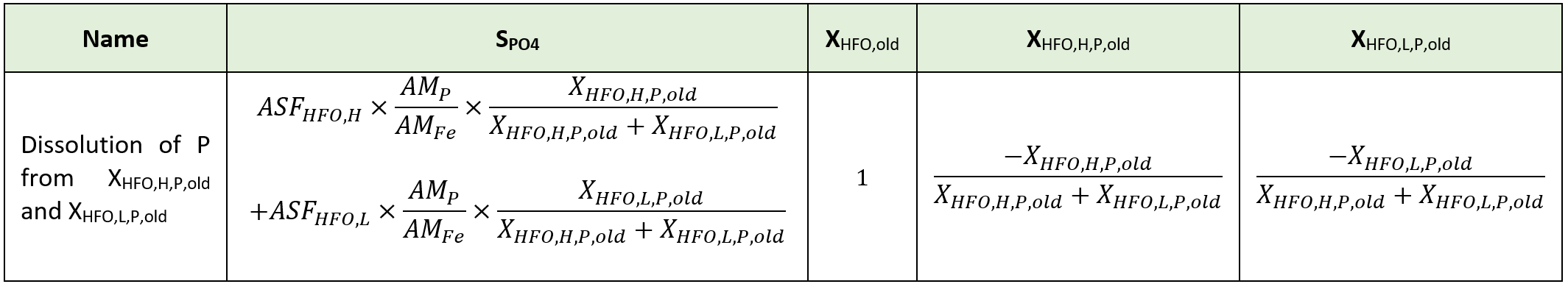

| XHFO,old | Aged unused hydrous ferric oxide (HFO,old) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | When there is excess ferric addition and not much SPO4 is available then XHFO,H and XHFO,L formed age into XHFO,old. These are incapable of removing SPO4. | g Fe.m-3 |

| XHFO,H,P | P-bound hydrous ferric oxide, high surface (HFO,H,P) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | The Fe-SPO4 complex formed with XHFO,H. | g Fe.m-3 |

| XHFO,L,P | P-bound hydrous ferric oxide, low surface (HFO,L,P) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | The Fe-SPO4 complex formed with XHFO,L. | g Fe.m-3 |

| XHFO,H,P,old | Aged P-bound hydrous ferric oxide, high surface (HFO,H,P,old) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Aged form of XHFO,H,P. | g Fe.m-3 |

| XHFO,L,P,old | Aged P-bound hydrous ferric oxide, low surface (HFO,L,P,old) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Aged form of XHFO,L,P. | g Fe.m-3 |

| XHAO,H | Active hydrous aluminium oxide, high surface (HAO,H) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Aluminium hydroxide with high surface area and high capacity to bind SPO4. Higher mixing condition results in more XHAO,H formation compared to XHAO,L. | g Al.m-3 |

| XHAO,L | Active hydrous aluminium oxide, low surface (HAO,L) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Aluminium hydroxide with low surface area and low capacity to bind SPO4. Poor mixing condition results in more XHAO,L formation compared to XHAO,H. | g Al.m-3 |

| XHAO,old | Aged unused hydrous aluminium oxide (HAO,old) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | When there is excess XHAO and not much SPO4 is available then XHAO and XHAO,L formed age into XHAO,old. These are incapable of removing SPO4. | g Al.m-3 |

| XHAO,H,P | P-bound hydrous aluminium oxide, high surface (HAO,H,P) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | The Al-SPO4 complex formed with XHAO,H. | g Al.m-3 |

| XHAO,L,P | P-bound hydrous aluminium oxide, low surface (HAO,L,P) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | The Al-SPO4 complex formed with XHAO,L. | g Al.m-3 |

| XHAO,H,P,old | Aged P-bound hydrous aluminium oxide, high surface (HAO,H,P,old) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Aged form of XHAO,H,P. | g Al.m-3 |

| XHAO,L,P,old | Aged P-bound hydrous aluminium oxide, low surface (HAO,L,P,old) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Aged form of XHAO,L,P. | g Al.m-3 |

| XCaCO3 | Calcium carbonate (CaCO3) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Essential chemical for pH control - a precipitate that forms readily | g TSS.m-3 |

| XACP | Amorphous calcium phosphate (ACP) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Elemental composition of Ca3(PO4)2 * 4H2O. | g TSS.m-3 |

| XBSH | Brushite (BSH) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Elemental composition of CaHPO4 * 2H2O. Forms at lower pH values than Struvite | g TSS.m-3 |

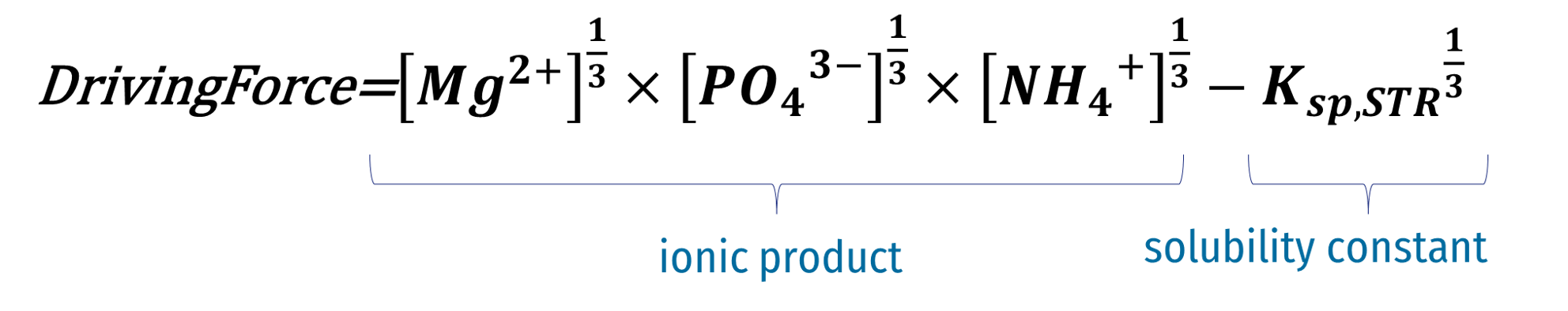

| XSTR | Struvite (STR) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Formed under anaerobic environments and has an elemental composition of MgNH4PO4 * 6H2O. | g TSS.m-3 |

| XVivi | Vivianite (Vivi) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Formed under anaerobic environments and has an elemental composition of Fe3(PO4)2 * 8H2O. | g TSS.m-3 |

| XFeS | Iron sulfide (FeS) | Sumo2S | Formed under anaerobic environments and is a precursor for pyrite formation. | g TSS.m-3 |

| H | Enthalpy | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | An energy-like property that is used to calculate temperature of a system. It flows from the influent unit to the plant. | MJ.m-3 |

| SALPHA | Alpha indicator | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A surrogate representing the surfactant composition in the wastewater. | unitless |

| SORPswitch | ORP driver for CASTO activity switches | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | A surrogate switch to calculate the activity of CASTOs. | unitless |

| GCO2 | Carbon dioxide gas (CO2) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Gaseous form represented in bubbles of wastewater system. | g TIC.m-3 |

| GCH4 | Methane gas (CH4) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Gaseous form represented in bubbles of wastewater system. | g COD.m-3 |

| GH2 | Hydrogen gas (H2) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Gaseous form represented in bubbles of wastewater system. | g COD.m-3 |

| GO2 | Oxygen gas (O2) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Gaseous form represented in bubbles of wastewater system. | g O2.m-3 |

| GNH3 | Ammonia gas (NH3) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Gaseous form represented in bubbles of wastewater system. | g N.m-3 |

| GN2 | Nitrogen gas (N2) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Gaseous form represented in bubbles of wastewater system. | g N.m-3 |

| GNO | Nitric oxide gas (NO) | Sumo4N | Gaseous form represented in bubbles of wastewater system. | g N.m-3 |

| GN2O | Nitrous oxide gas (N2O) | Sumo4N | Gaseous form represented in bubbles of wastewater system. | g N.m-3 |

| GH2S | Hydrogen sulfide gas (H2S) | Sumo2S | Gaseous form represented in bubbles of wastewater system. | g S.m-3 |

| GCO2,atm | Carbon dioxide gas (CO2) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Gaseous form represented in the atmosphere around wastewater systems. | %v/v |

| GCH4,atm | Methane gas (CH4) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Gaseous form represented in the atmosphere around wastewater systems. | %v/v |

| GH2,atm | Hydrogen gas (H2) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Gaseous form represented in the atmosphere around wastewater systems. | %v/v |

| GO2,atm | Oxygen gas (O2) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Gaseous form represented in the atmosphere around wastewater systems. | %v/v |

| GNH3,atm | Ammonia gas (NH3) | Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Gaseous form represented in the atmosphere around wastewater systems. | %v/v |

| GN2,atm | Nitrogen gas (N2) | Mini_Sumo, Sumo1, Sumo2, Sumo2C, Sumo2S, Sumo4N | Gaseous form represented in the atmosphere around wastewater systems. | %v/v |

| GNO,atm | Nitric oxide gas (NO) | Sumo4N | Gaseous form represented in the atmosphere around wastewater systems. | %v/v |

| GN2O,atm | Nitrous oxide gas (N2O) | Sumo4N | Gaseous form represented in the atmosphere around wastewater systems. | %v/v |

| GH2S,atm | Hydrogen sulfide gas (H2S) | Sumo2S | Gaseous form represented in the atmosphere around wastewater systems. | %v/v |

| SMM,index | Methyl mercaptan production index | Sumo2S | A surrogate for indicating the potential for odor generation at a wastewater facility. | Unitless |

¶ Biological processes

¶ BOD removal

BOD removal from is characterized as soluble substrate component uptake by biomass and used for growth and respiration.

The colloidal biodegradable components are flocculated into particulate components (see Flocculation paragraph). The particulate components are hydrolyzed into soluble components thus biomass can grow on them (see Hydrolysis paragraph).

¶ Biomasses involved in BOD removal

¶ Ordinary heterotrophic organisms, XOHO

Generalist facultative ordinary hetrotrophic organisms that consume different soluble biodegradable organics including SB, SVFA, and XMEOL and can perform biological removal under aerobic, anoxic, and anaerobic environments. They are also responsible for hydrolysis of the particulates. In MiniSumo and Sumo1, they perform one step denitrification, meaning from SNOx to SN2. In other models they follow two steps, SNO3 reduction to SNO2, and SNO2 reduction to SN2.

| Biological processes | Concepts description |

|---|---|

| Aerobic growth on VFA, O2 |

Growth on SVFA under aerobic conditions. Requires SO2, nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH. |

| Anoxic growth on VFA, NO2- |

Growth on SVFA under anoxic conditions. This is the second step of denitrification in Sumo2, Sumo2C and Sumo2S), SNO2 is reduced into SN2. This process is not described in Sumo1 and MiniSumo. Requires SNO2, nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH. |

| Anoxic growth on VFA, NO3- |

Growth on SVFA under anoxic conditions. This is the denitrification process in Sumo1 and MiniSumo: SNO3 is reduced in SN2. This is the first step of denitrification in Sumo2, Sumo2C and Sumo2S): SNO3 is reduced into SNO2. Requires SNO3, nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH. |

| Aerobic growth on SB, O2 |

Growth on SB under aerobic conditions. Requires SO2, nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH |

| Anoxic growth on SB, NO2- |

Growth on SB under anoxic conditions. This is the second step of denitrification in Sumo2, Sumo2C and Sumo2S), SNO2 is reduced into SN2. This process is not described in Sumo1 and MiniSumo. Requires SNO2, nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH |

| Anoxic growth on SB, NO3- |

Growth on SB under anoxic conditions. This is the denitrification process in Sumo1 and MiniSumo: SNO3 is reduced in SN2. This is the first step of denitrification in Sumo2, Sumo2C and Sumo2S): SNO3 is reduced into SNO2. Requires SNO3, nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH. |

| SB fermentation with high VFA (OHO growth, anaerobic) |

Growth on SB under anaerobic conditions. OHO Fermenters have different growth rate of 0.3 d-1 and digesters have different KSB,ana of 350 mgCOD/L Produce SVFA as fermentation product and SH2. Under high SVFA concentration, the yield of SH2 production is higher (less SVFA produced). Requires nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH. |

| SB fermentation with low VFA (OHO growth, anaerobic) |

Growth on SB under anaerobic conditions. OHO Fermenters have different growth rate of 0.3 d-1 and digesters have different KSB,ana of 350 mgCOD/L Produce SVFA as fermentation product and SH2. Under low SVFA concentration, the yield of SH2 production is lower (more SVFA produced). Requires nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH. |

| Aerobic growth on SMEOL, O2 |

OHO aerobic growth on methanol in order to consum any residual methanol from anoxic carbon dosage for denitrification. Requires SO2, nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH. |

| OHO decay | OHO decay process under anoxic and aerobic conditions. This process release XB,e and XE (death-regeneration concept). |

| OHO anaerobic decay | OHO decay process under anaerobic conditions. This process release XB,e and XE,ana (death-regeneration concept). |

¶ Anoxic methanol utilizers, XMEOLO

Specialist heterotrophic organisms responsible for removal of XMEOL. Only found in systems with methanol addition and compete with OHOs during denitrification process. In Sumo1, they perform one step denitrification, meaning from SNOx to SN2. Is other models they follow two steps, SNO3 reduction to SNO2, and SNO2 reduction to SN2.

| Biological processes | Concepts description |

|---|---|

| MEOLO growth, NO2 |

Growth on SMEOL under anoxic conditions. This is the second step of denitrification in Sumo2, Sumo2C and Sumo2S), SNO2 is reduced into SN2. This process is not described in Sumo1 and MiniSumo. Requires SNO2, nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH |

| MEOLO growth, NO3 |

Growth on SMEOL under anoxic conditions. This is the denitrification process in Sumo1 and MiniSumo: SNO3 is reduced in SN2. This is the first step of denitrification in Sumo2, Sumo2C and Sumo2S): SNO3 is reduced into SNO2. Requires SNO3, nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH. |

| MEOLO decay | MEOLO decay process under anoxic and aerobic conditions. This process release XB,e and XE (death-regeneration concept). |

| MEOLO anaerobic decay | MEOLO decay process under anaerobic conditions. This process release XB,e and XE,ana (death-regeneration concept). |

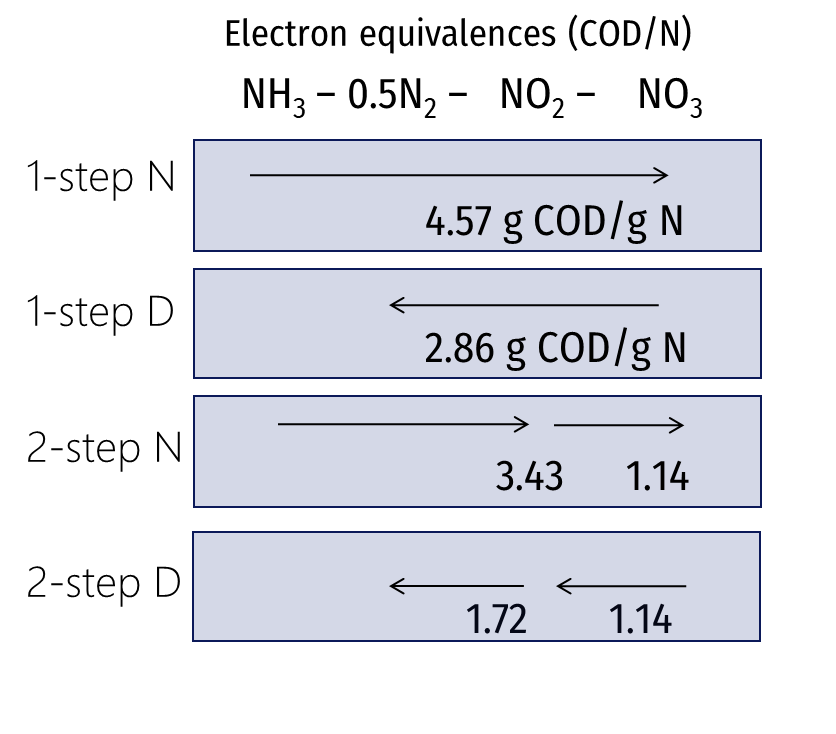

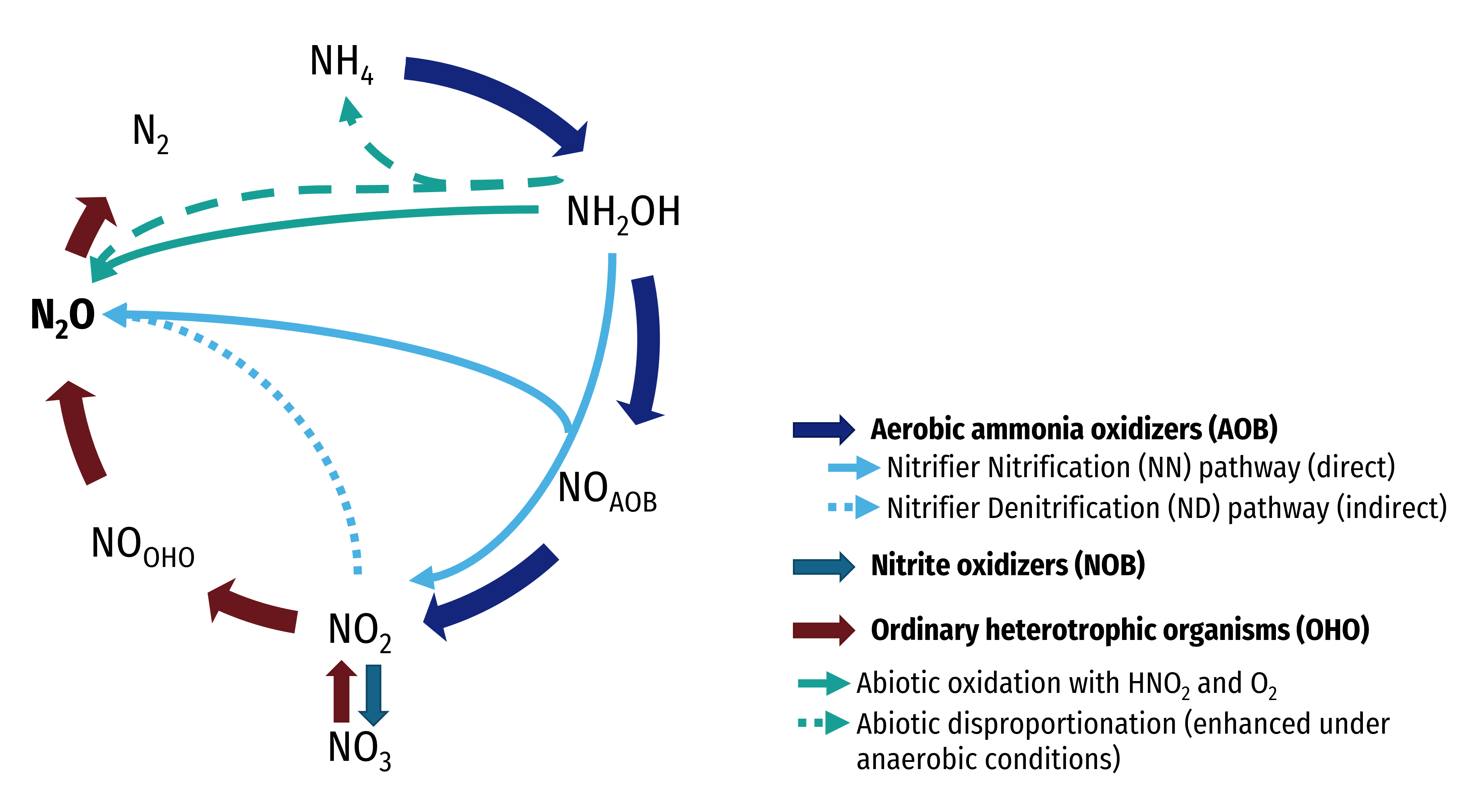

¶ Nitrogen removal

¶ Nitrification model

Nitrification rate is the most important parameter in design and reliable simulation of BNR (Biological Nutrient Removal) plants. The maximum specific growth rate of nitrifiers ranges from 0.2 to 1 d-1 for different wastewater. This parameter should be considered as part of wastewater characterization.

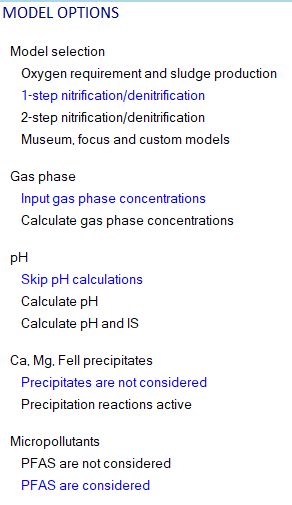

There are three models available in Sumo to describe the process on three layer of details:

- Mini_Sumo and Sumo1 – one step nitrification process

- one nitrifying organism (XNITO),

- ammonia (SNHx) and nitrate (SNOx) as nutrients

- Sumo2, Sumo2C, and Sumo2S – two step nitrification process

- Three organisms

- ammonia oxidizing bacteria (XAOB)

- nitrite oxidizing bacteria (XNOB)

- Anamox organisms (XAMX)

- Three nutrients

- Ammonia (SNHx), nitrite (SNO2), nitrate (SNO3)

- XAOB kinetics are the first step and rate limiting

- Three organisms

- Sumo4N - detailed nitrification and GHG emission model

- 4-step nitrification model from Pocquet et al., 2016

- 4-step denitrification model from Hiatt and Grady, 2008

- NO considered as cell internal intermediate

Sumo4N model is describe in details in Focus models mechanisms chapter.

¶ Biomasses involved in nitrification

¶ Aerobic nitrifying organisms, XNITO

Obligate aerobic autotrophic organism responsible for complete nitrification, from SNHx to SNOx in MiniSumo and Sumo1. It represents a combination of AOBs and NOBs for simplification in the referred models.

| Biological processes | Concepts description |

|---|---|

| NITO growth |

NITO growth process, using SNHx as electron donor. SNHx is oxidized in SNO3 in one step. SCO2 is used as carbon source. Requires SO2, nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH. |

| NITO decay | NITO decay process under anoxic and aerobic conditions. This process release XB,e and XE. |

| NITO anaerobic decay | NITO decay process under anaerobic conditions. This process release XB,e and XE,ana . |

¶ Aerobic ammonia oxidizers, XAOB

Obligate aerobic autotrophic organism responsible for the first step in nitrification, from SNHx to SNO2 in Sumo2, Sumo2C and Sumo2S.

| Biological processes | Concepts description |

|---|---|

| AOB growth |

AOB growth process, using SNHx as electron donor. This is the first step of nitrification: SNHx is oxidized in SNO2 SCO2 is used as carbon source. Requires SO2, nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH. |

| AOB decay | AOB decay process under anoxic and aerobic conditions. This process release XB,e and XE. |

| AOB anaerobic decay | AOB decay process under anaerobic conditions. This process release XB,e and XE,ana . |

¶ Nitrite oxidizers, XNOB

Obligate aerobic autotrophic organism responsible for the second step in nitrification, from SNO2 to SNO3 in Sumo2, Sumo2C and Sumo2S.

| Biological processes | Concepts description |

|---|---|

| NOB growth |

NOB growth process, using SNO2 as electron donor. This is the second step of nitrification: SNO2 is oxidized in SNO3 SCO2 is used as carbon source. Requires SO2, nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH. |

| NOB decay | NOB decay process under anoxic and aerobic conditions. This process release XB,e and XE. |

| NOB anaerobic decay | NOB decay process under anaerobic conditions. This process release XB,e and XE,ana . |

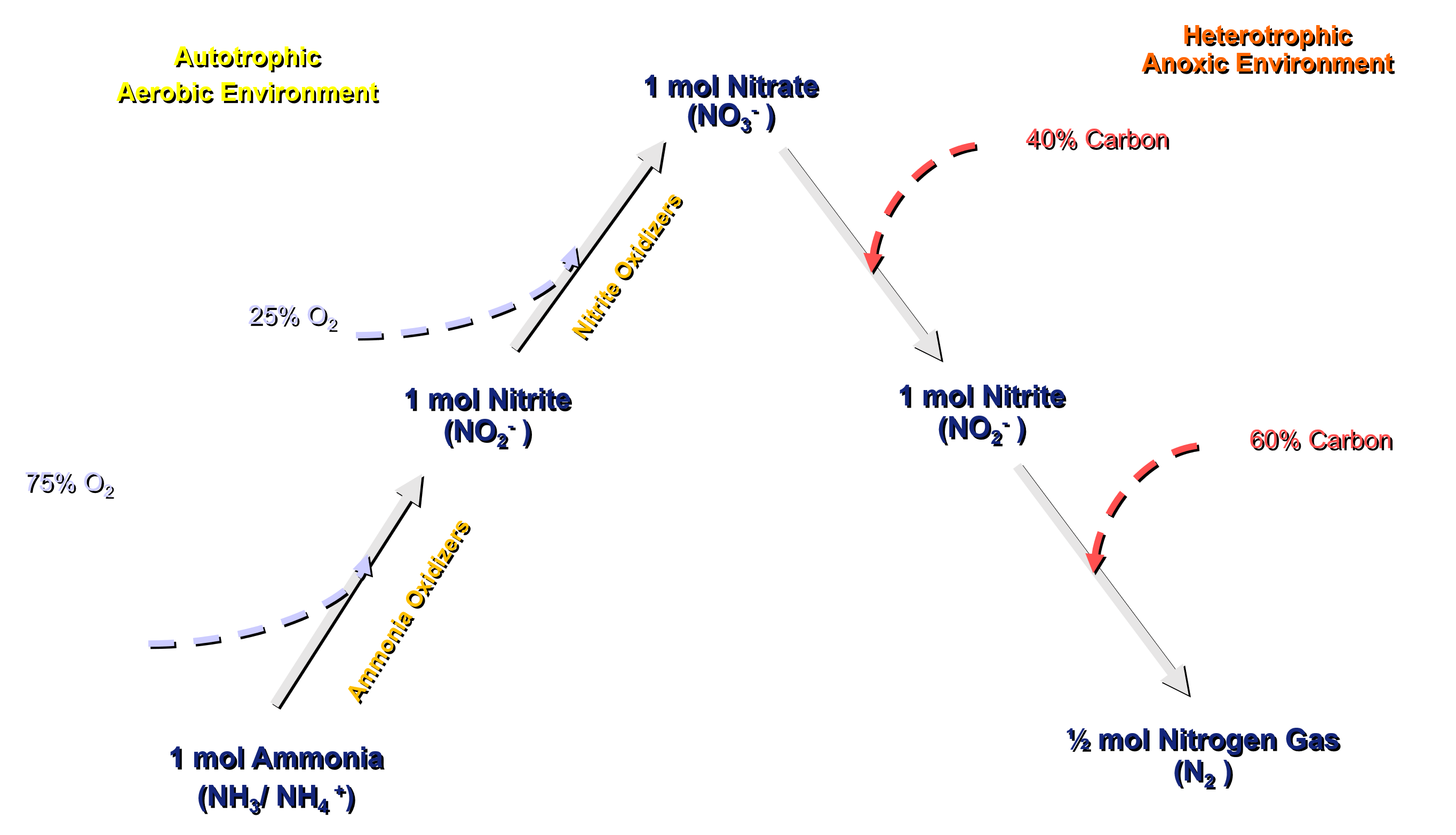

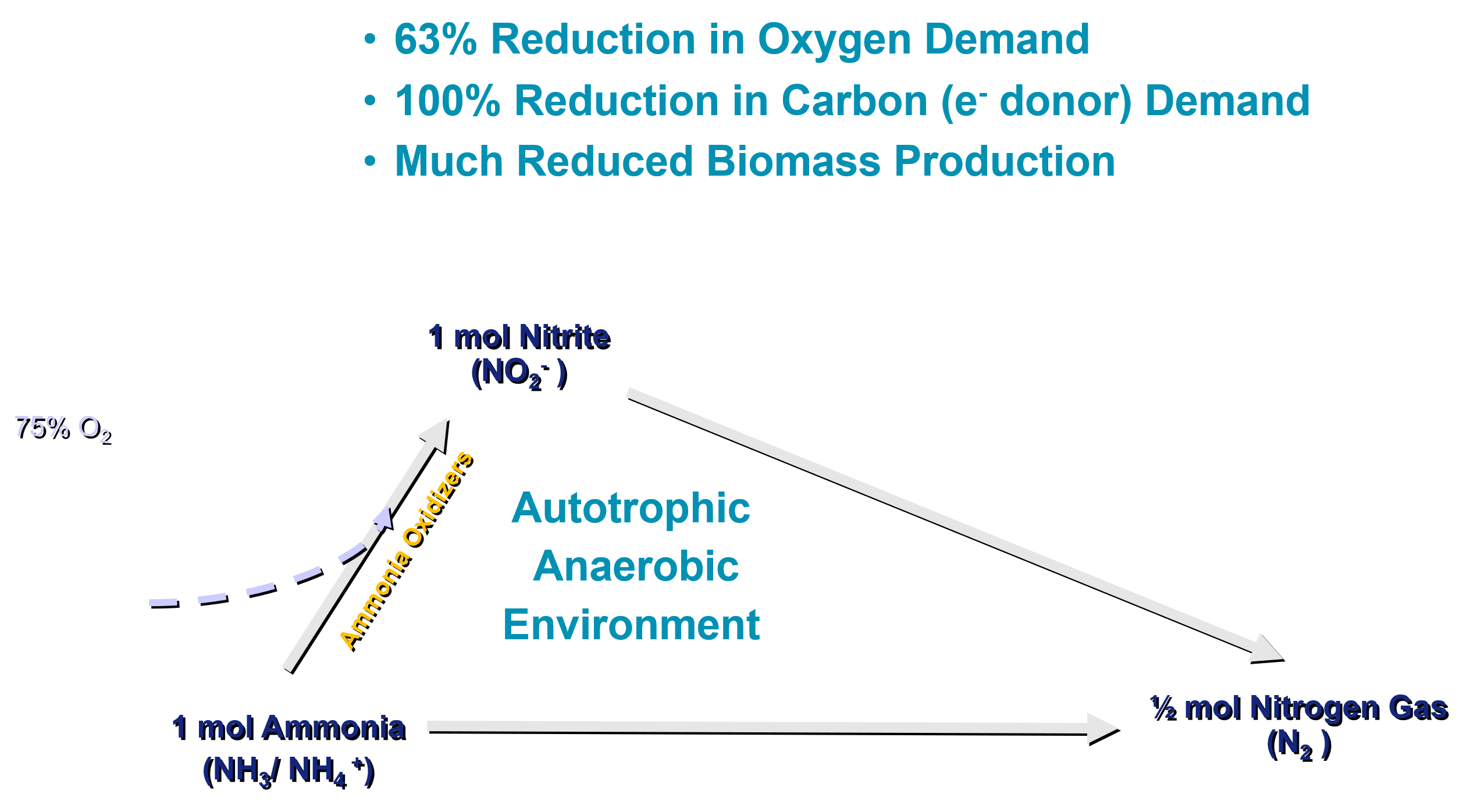

¶ Anammox organisms, XAMX

Anammox is a chemoautotrophic anaerobic bacteria that oxidizes ammonium with nitrite as the electron acceptor and with CO2 as the main carbon source. They are implemented in Sumo2, Sumo2C, Sumo2S and Sumo4N models.

Anammox are slow growers and have a long doubling time. Their growth reaction stoichiometry is described by Strous (1998, 1999):

NH4+ + 1.32 NO2- + 0.066 HCO3- + 0.13 H+ = 0.26 NO3- + 1.02 N2 + 0.066 CH2O0.5N0.15 + 2.03 H2O

This reaction allows saving up to 63% of oxygen demand and 100% of carbon requirement (Figure 2.2) compared to a full nitrification and denitrification pathway for nitrogen removal (Figure 2.1).

The Anammox organisms are modelled in Sumo2, Sumo2C, Sumo2S and Sumo4N models. The model includes description of anammox growth, decay and anaerobic decay.

The stoichiometry of Anammox growth in Sumo is derived from the stoichiometry proposed by Strous. Two stoichiometric parameters are introduced: the amount of nitrite utilised per mol of ammonia oxidized, and the amount of nitrate produced per mol of ammonia utilised.

| YAMX,NO2 | Yield of AMX on NO2 | 1.32 | mol NO2/mol NH4 |

| YAMX,NO3 | Yield of AMX on NO3 | 0.26 | mol NO3/mol NH4 |

The stoichiometric coefficient expressions are then obtained by applying the full elemental balance methodology from Takacs et al. (2007).

A generic biomass composition CaCHaHOaONaN is considered. The theoretical oxygen demand of this biomass is by definition:

BioThOD = (aC + aH/4 - 3 * aN/4 - aO/2) * 2 * AMO

with AMO as the atomic mass of oxygen.

Considering uncharged species, the Anammox reaction is set up as:

(vNH3 + aN) * NH3 + vHNO2 * HNO2 + aC * CO2 = CaCHaHOaONaN + vN2 * N2 + vHNO3 * HNO3 + vH2O * H2O

With vNH3, vHNO2, vN2, vHNO3 and vH2O the stoichiometric coefficients of the ammonia oxidation with nitrite reaction.

Five equations can be derived from this reaction:

- Two equations for the definitions of the stoichiometric parameters that are chosen:

- YNO2 = vHNO2 /vNH3

- YNO3 =v HNO3 /vNH3

- Three mass balances can be expressed for hydrogen, nitrogen and oxygen:

- H balance: 3 * (vNH3 + aN) + vHNO2 = aH + vHNO3 + 2 * vH2O

- N balance: vNH3 + vHNO2 = vHNO3 + 2 * vN2

- O balance: 2 * vHNO2 + 2 * aC = aO + 3 * vHNO3 + vH2O

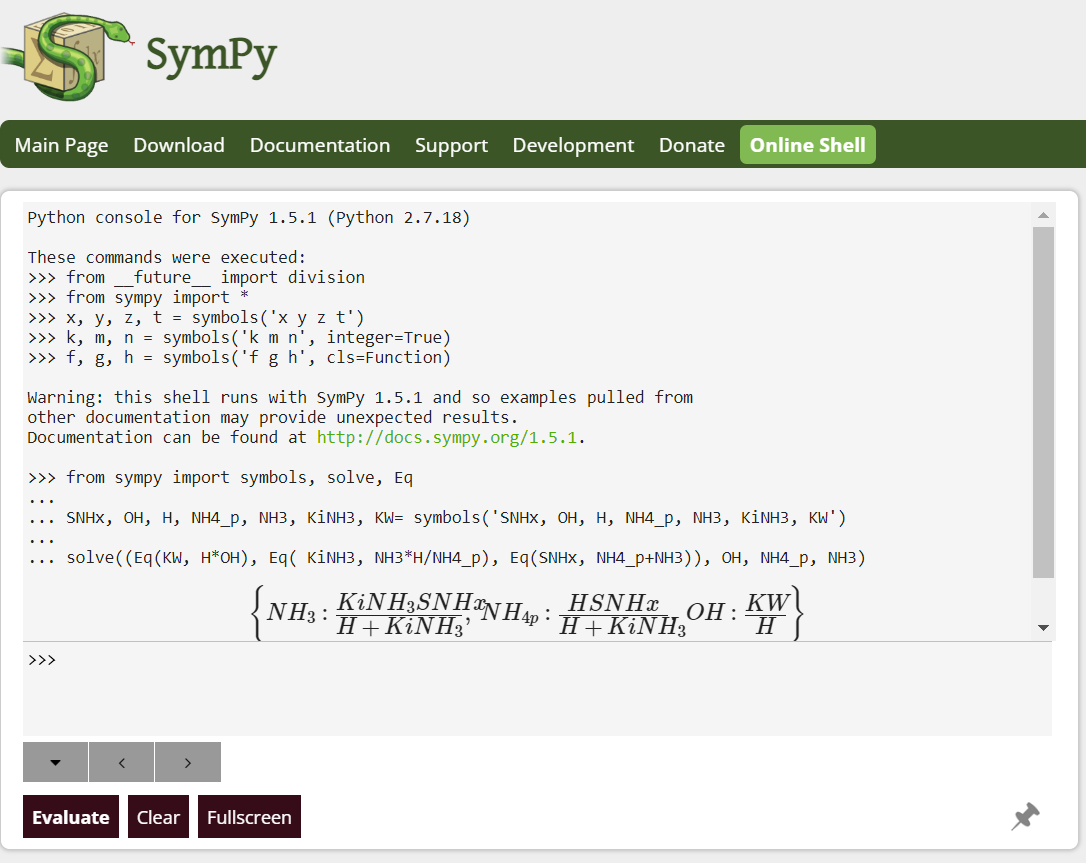

These 5 equations can be used to find the 5 unknowns: vNH3, vHNO2, vHNO3, vN2 and vH2O.The following code is executed in python for the symbolic resolution:

from sympy import symbols, solve, Eq

NH3, vNH3, HNO2, vHNO2, CO2, H3PO4, N2, vN2, HNO3, vHNO3, H2O, vH2O, YNO2, YNO3, aC, aH, aO, aN =

symbols('NH3, vNH3, HNO2, vHNO2, CO2, H3PO4, N2, vN2, HNO3, vHNO3, H2O, vH2O, YNO2, YNO3, aC, aH, aO, aN')

solve(( Eq(YNO2, vHNO2*N/(vNH3*N)), Eq(YNO3, vHNO3*N/(vNH3*N)), Eq( 3*(vNH3+aN)+vHNO2,aH+vHNO3+2*vH2O), Eq( vNH3+vHNO2,vHNO3+2*vN2), Eq(2*vHNO2+2*aC,aO+3*vHNO3+vH2O)), vNH3, vHNO2, vHNO3, vN2, vH2O)

The result is (vH2O is not shown as not included in the model):

vNH3 = (4 * aC + aH - 3 * aN - 2 * aO) /(-3 * YNO2 + 5 * YNO3 + 3)

vHNO2 = YNO2 * (4 * aC + aH - 3 * aN - 2 * aO)/(-3 * YNO2 + 5 * YNO3 + 3)

vHNO3 = YNO3 * (4 * aC + aH - 3 * aN - 2 * aO)/(-3 * YNO2 + 5 * YNO3 + 3)

vN2 = (4 * YNO2 * aC + YNO2 * aH - 3 * YNO2 * aN - 2 * YNO2 * aO - 4 * YNO3 * aC - YNO3 * aH + 3 * YNO3 * aN +

+ 2 * YNO3 * aO + 4 * aC + aH - 3 * aN - 2 * aO) /(2 * (-3 * YNO2 + 5 * YNO3 + 3))

These coefficients must be converted per gram of biomass COD (arbitrary reference in all biomass growth reactions) and in g N. Then, vNH3, vHNO2 and vHNO3 are multiplied by AMN/BioThOD and vN2 is multiplied by 2*AMN/BioThOD. The coefficient aN is the nitrogen content of the biomass, iN,Bio. As nitrogen content of the biomass is explicitly expressed, the definition of the theoretical COD of the biomass is revised as:

BioThOD=(aC+aH/4-aO/2)*2*AMO.

The convention of the negative signs for consumed components is also added. This results in the following stoichiometric coefficient expressions:

vNH3 = -(3 * iN,BIO * AMO + 2 * AMN) /(5 * YAMX,NO3 + 3 - 3 * YAMX,NO2) /AMO

vHNO2= -YAMX,NO2 /(5 * YAMX,NO3 + 3 - 3 * YAMX,NO2) * (3 * iN,BIO * AMO + 2 * AMN) /AMO

vHNO3= YAMX,NO3 /(5 * YAMX,NO3 + 3 - 3 * YAMX,NO2) * (3 * iN,BIO * AMO + 2 * AMN) /AMO

vN2 = 2 * (YAMX,NO3 * AMN - 1 * AMN - 1 * YAMX,NO2 * AMN + 4 * YAMX,NO3 * iN,BIO * AMO -

-3 * YAMX,NO2 * iN,BIO * AMO) /AMO /(3 * YAMX,NO2 - 5 * YAMX,NO3 - 3)

| Biological processes | Concepts description |

|---|---|

| Growth |

AMX growth process, using SNHx as electron donor and SNO2 as electron acceptor. SNO3 and SN2 are produced by the reaction. The stoichiometry is described above. SCO2 is used as carbon source. Requires SNHx, SNO2, nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH. |

| Decay | AMX decay process under anoxic and aerobic conditions. This process release XB,e and XE. |

| Anaerobic decay | AMX decay process under anaerobic conditions. This process release XB,e and XE,ana . |

Strous, M., Heijnen, J., Kuenen, J. et al. The sequencing batch reactor as a powerful tool for the study of slowly growing anaerobic ammonium-oxidizing microorganisms. Appl Microbiol Biotechnol 50, 589–596 (1998). https://doi.org/10.1007/s002530051340

Strous, M., Fuerst, J., Kramer, E. et al. Missing lithotroph identified as new planctomycete. Nature 400, 446–449 (1999). https://doi.org/10.1038/22749

Takács, I., Vanrolleghem, P.A., Wett, B., Murthy, S., 2007. Elemental balance based methodology to establish reaction stoichiometry in environmental modeling. Water Sci. Technol. 56, 37–41.

¶ Impact of operating conditions and design on nitrification

Nitrification is impacted by:

- dissolved oxygen level

- liquid temperature

- pH and alkalinity

- Low mixing condition or floc size can cause diffusion issues and cause reduction in nitrification rate. Half saturation for oxygen for nitrifiers can be possible calibration factor to mimic this limitation.

If the ammonia level in the aerobic cell is close to half saturation, then its important to simulate the reactor as plug flow.

¶ Sidestream and mainstream nitrification

Two types of process unit model options are available for selection on configure tab: Mainstream or Sidestream (these can be selected from the configure tab if i.e. the CSTR is selected)

The growth rate and half-saturation for sidestream reactors are different due to possible diffusion issues, inhibitory compounds in centrate, and temperature.

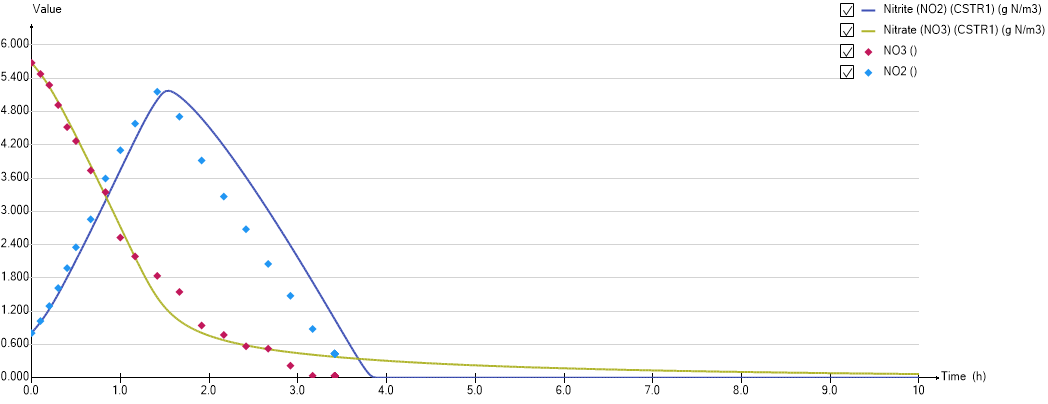

¶ Measuring specific growth rate

Two different tests can be performed to measure nitrifiers growth rate:

- High F/M test – 7 days

- Batch test: Small initial nitrifier concentration combined with high initial ammonia concentration

- Exponential response of NOx to estimate growth rate

- pH and alkalinity control are especially important

- This can be done with different wastewater to identify possible inhibition, download and see the High FM.msumo example

- Washout test – several days

- Operating a flow through CSTR just at correct HRT initially filled with nitrifying sludge

- Important step to identify flow rate to the CSTR just enough to cause a washout

- There is little to no growth of nitrifiers during the test and test is performed using actual plant influent

- See Washout test.msumo example

¶ Denitrification model

Denitrification is the reduction process of oxidized forms of oxygen, used as electron acceptor in the growth process of heterotrophic organisms. If denitrification is complete, these electron acceptors are reduced sequentially to nitrogen gas (SN2).

¶ Impact of operating conditions and design on denitrification

Denitrification is impacted by the availability of a carbon source. Knowing RBCOD concentration is extremely important for nitrogen removal design and modelling. The denitrification rate is then controlled by:

- the concentration of readily biodegradable COD (SB plus SVFA) in raw wastewater

- the addition of an external carbon source

- the rate of hydrolysis under anoxic condition (when other carbon sources are depleted)

¶ Model specifications under anoxic conditions

- MiniSumo

- One biomass involved in denitrification: OHOs

- One step denitrification, SNO3 to SN2

- Growth of heterotrophic biomass on SB reduced by reduction factor as nor SVFA and neither methanol utilizers are part of the model

- Decay of OHO also reduced under anoxic condition

- Hydrolysis reduced under denitrification using the reduction factor

- Sumo1

- 3 biomasses involved in denitrification: OHOs, CASTOs and MEOLOs

- One step denitrification, SNO3 to SN2

- Hydrolysis reduced under anoxic conditions

- Growth of OHO on SB and SVFA is reduced under anoxic conditions

- First substrate preference is SVFA over SB, reaction is reduced for SB until SVFA disappears

- Methanol utilizers and their respective kinetics and stoichiometry is included

- PAOs and GAOs perform denitrification on stored compounds and have a reduction factor

- All biomass has reduction factor for decay even for methanol utilizers

- Sumo2, Sumo2C and Sumo2S

- 3 biomasses involved in denitrification: OHOs, CASTOs and MEOLOs

- Two step denitrification: SNO3 to SNO2 to SN2

- All the reactions are same as Sumo1 but with 2 steps of denitrification

- Carbon, nitrate and nitrite switching functions allow to simulate nitrite accumulation in PdNA processes. See PdNA model description below.

- Sumo2S - Sulphur-oxidizing organisms (SOO) are involved in denitrification in presence of H2S and elemental sulphur

- Sumo4N

- Sumo4N model is describe in details in Focus models mechanisms chapter.

¶ PdNA model

Successful implementation of mainstream partial denitrification and anammox (PdNA) process is critical for meeting the future’s stringent effluent total nitrogen targets with low energy demand and carbon addition costs. PdNA relies on dosing enough carbon (of a specific type) to an anoxic zone so that the heterotrophic denitrification produces nitrite (through partial denitrification), which is necessary for the growth of anammox. A good design and identification of an optimized operational strategy is impossible without being able to model such a complex biological process.

The current models do not allow nitrite accumulation based on the type of carbon and the carbon-to-nitrate ratio of the system. This resulted in an inability to evaluate the correct design conditions for growing anammox alongside the heterotrophic denitrifiers, frequently leading to overestimating the carbon dosage.

To support the efforts of design and research engineers, Sumo24 two-step nitrification-denitrification models have been improved to simulate the PdNA process. Based on the carbon-to-nitrate ratio, a mechanism associated with using methanol and volatile fatty acids as the two carbon sources is introduced, which allows for nitrite accumulation under low carbon addition. The model developed is calibrated using data from the literature.

The model behave as follow:

- While there is some NO3, nitrate is denitrified into nitrite under 2 alternative conditions:

- if the VFA is low

- if the VFA is high but there is no NO2

- Denitrification of nitrite to N2 when nitrate is depleted

¶

Key model details of the denitrification process

- Under anoxic conditions, the yield coefficients are reduced (compared to aerobic conditions) and is particularly important for denitrification kinetics analysis.

- Reduction factor for anoxic growth kinetic of OHOs

- In Sumo the default value of 0.6 is used for denitrification while

- In real plants it ranges from 0.3 to 0.85 and

- it can depend on system design or operation, represents degree of removal rate and process SRT.

- It can be used for calibration

- Results in lower rate of substrate utilization and endogenous decay. This is because not all the biomass are facultative and don’t participate in denitrification.

- is implemented as relative energy generated is higher with O2 as electron acceptor than with nitrate.

- The actual value be determined by performing OUR and NUR test, see Anoxic reduction factor.msumo

- Denitrification batch tests are done to identify the denitrification rate kinetics, see Denitrification test MLSS.msumo

- In Sumo the default value of 0.6 is used for denitrification while

- Inhibition due to oxygen is simulated using an inverse Monod also referred as a switching function

- (KO2)/((KO2) + (SO2)), dissolved oxygen inhibits denitrification reactions

- This value is 0.15 g O2/m3, however, this is an important constant that can be used to calibrate denitrification performance, especially in case of large flocs, deep tanks, and not well mixed conditions.

- A high value of the constant means, more denitrification under partially aerobic conditions, can be used for calibration

- Specific denitrification rate (g N/g VSS/h) is not a model parameter but is a calculated variable

¶ Phosphorus removal

Biological phosphorus removal is achieved in activated sludge processes via two main pathways:

- Removal by biomass synthesis

Incorporation into molecules building cell walls, DNA, ATP as 1-2% of these is phosphorus. This process can remove at least 30% of P from influent and transfer it to the sludge. - Enhanced biological P removal

This chapter focuses on this process as the “luxury uptake” of polyphosphate once the conditions of the plant are set properly.

¶ Enhanced biological phosphorus removal (EBPR) processes

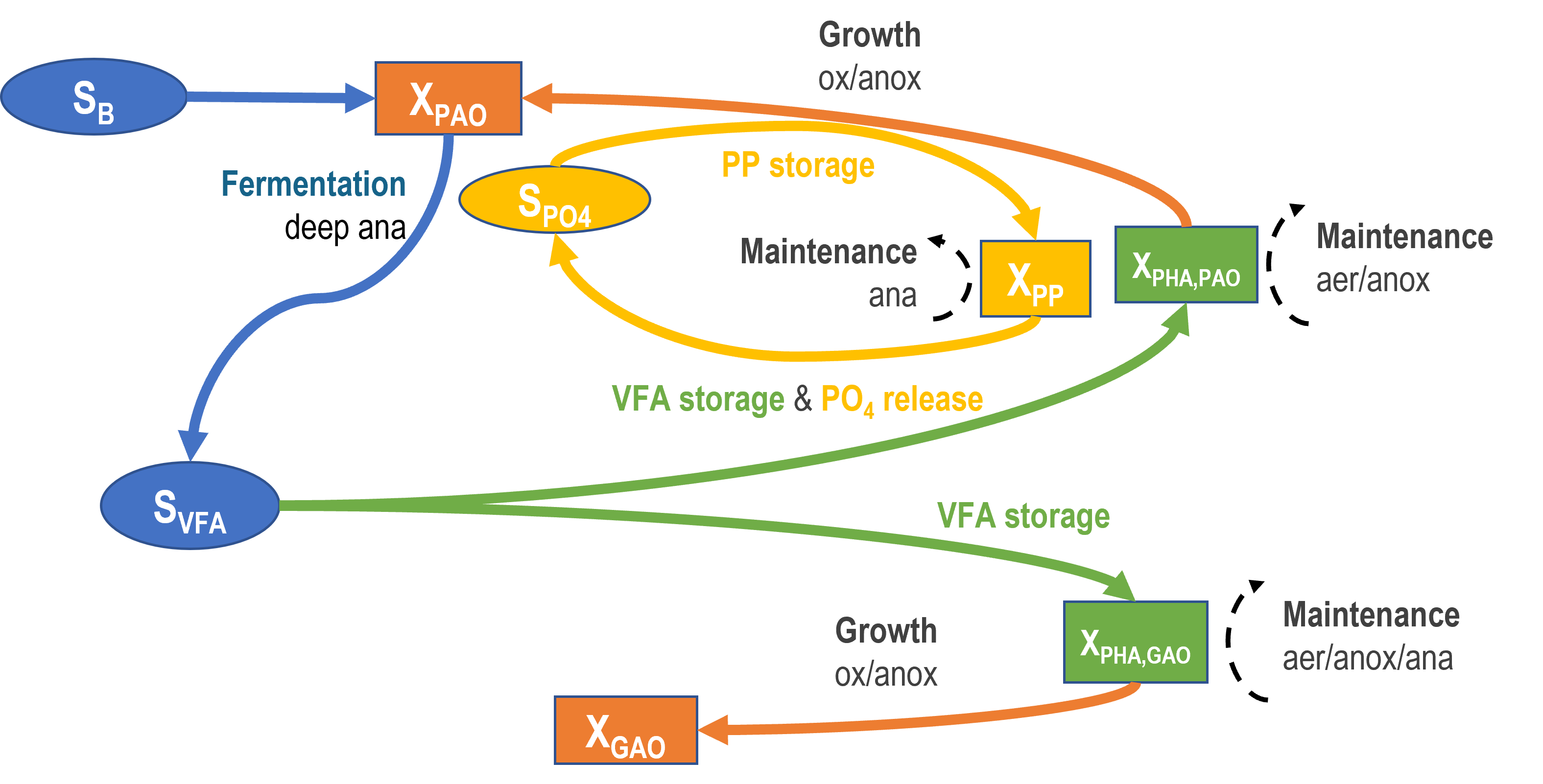

Sumo uses a model where two biomass fractions compete for the volatile fatty acids (VFA): one of them storing phosphates (phosphorus accumulating organisms, PAO) and the other one storing glycogen (glycogen accumulating organisms, GAO). These biomass fractions are represented as one unified biomass (carbon storing organisms, CASTO) in the model, however the processes that are specific to PAO or GAO are differentiated when external (ambient conditions) or internal (metabolism) driving forces require. The proportion between GAOs and PAOs is tracked by the amount of stored poly-hydroxy-alkanoates (PHA,GAO and PHA,PAO respectively) relative to all stored carbon (XSTC = XPHA,PAO + XPHA,GAO) in the system.

Note that GAOs are storing both PHA and glycogen as carbon storage, but in Sumo only PHA storage is accounted for as a state variable.

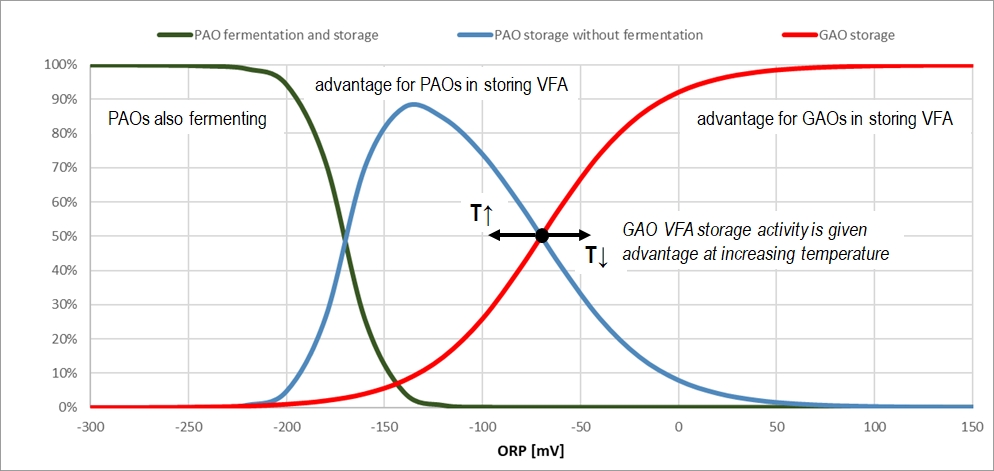

A logistic ORP switch function is employed to control the competition between VFA storage by GAOs and PAOs: at low ORP, GAO storage is inhibited and PAO storage is favored. Another ORP switch function is used to control the fermentation activity of Tetrasphaera-like PAOs under deep ORP regime.

In order to account for the lag in the biomass response following a change in the ORP (which can happen rapidly), a regulating role state variable (SOPRswitch, called as “ORP driver for CASTO activity switches”) was introduced to the model, along with a process that changes the value of this variable according to the following first-order kinetics:

dSORPswitch/dt = kORPswitch * (ORP + offsetORPswitch – SORPswitch)

where:

- ORP is the actual ORP derived from actual concentrations of O2, NOx, CH4 and H2 (as well as H2S in models involving sulfur);

- offsetORPswitch is a simple constant value that transposes SORPswitch values into the positive range (required by the solver algorithm);

- kORPswitch is the kinetic rate that represents the ORP time lag.

The effect is that SORPswitch follows ORP with a lag depending on the actual difference from the actual ORP. For small changes in the latter, SORPswitch is quick to catch up, while for abrupt changes it takes time for SORPswitch to catch up with ORP, resulting in a less hectic timeline of SORPswitch compared to ORP. The response time can be adjusted by manipulating the kORPswitch parameter. The default value of the kORPswitch parameter is 24 d-1, to allow for changes to happen in the order of magnitude of an hour (accommodating the model to be applied to dynamic systems like SBRs using the default parameter).

The PAO/GAO VFA storage mechanisms have been set in all plantwide process models to be driven by the new SORPswitch variable instead of ORP.

¶ ORP model

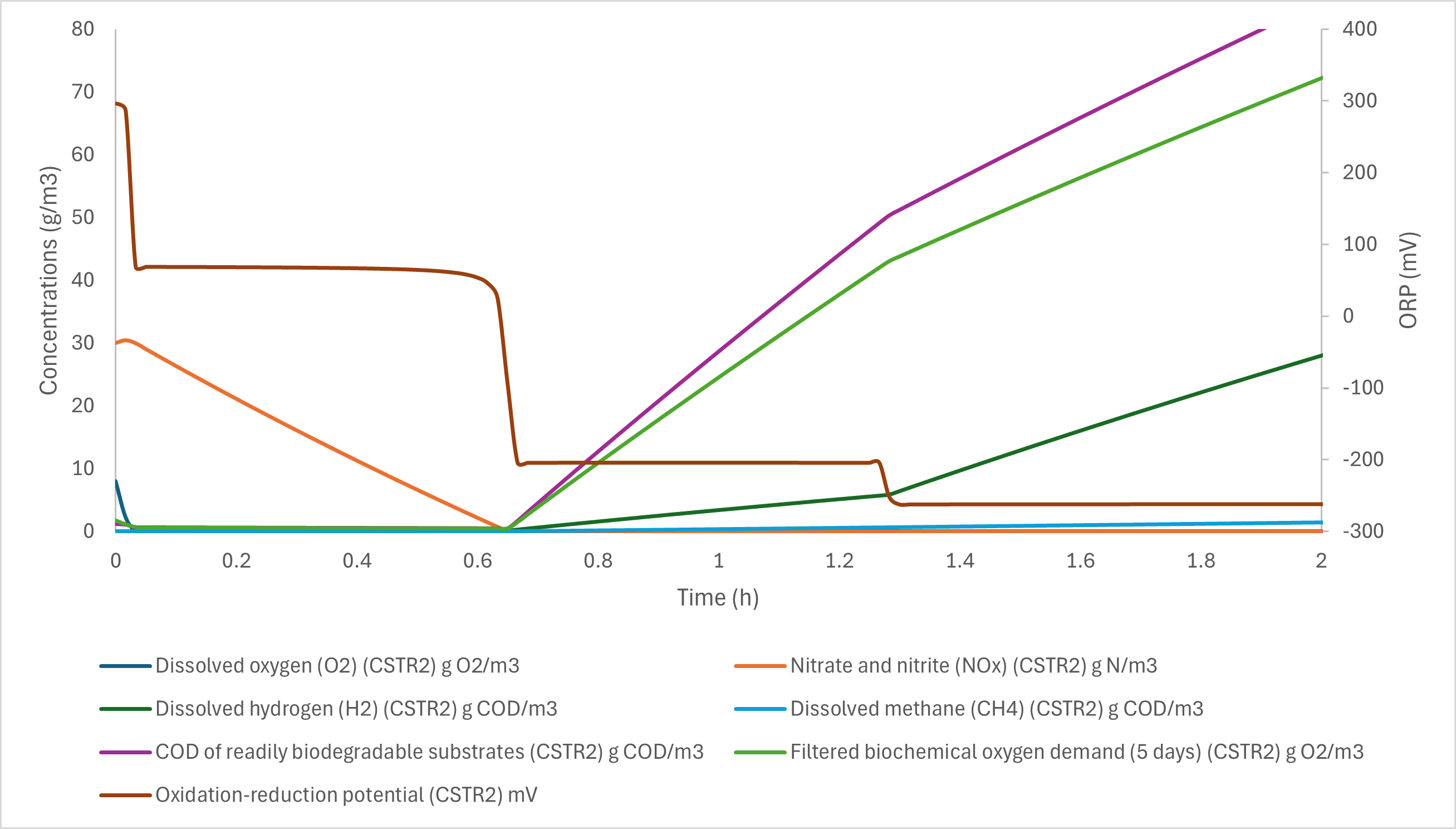

The oxidation-reduction potential is usually difficult to measure accurately in wastewater. The ORP value is estimated in the model, depending on the conditions:

- Under aerobic conditions, it considers a maximum of +300 mV value, that is modulated with the depletion of dissolved oxygen towards the anoxic maximum value (+70 mV)

- Under anoxic conditions, it considers a maximum of +70 mV value, that is modulated with the depletion of nitrates plus nitrites

- Under anaerobic conditions, the ratio of the production rate of H2 and CH4 (calculated as Anaerobic Activity Rate AAR), related to the rbCOD degradation rate (SVFA, SB and SMEOL degradation rate) is used as an indicator of the anaerobic activities. The higher this ratio, the lower the ORP value.

The final ORP is the maximum of the aerobic, anoxic and anaerobic ORP.

¶ Biomass involved in BioP: Carbon storing organisms, XCASTO

| Biological processes | Concepts description |

|---|---|

| CASTO growth on PHA,PAO and PHA,GAO, O2 |

PHA,PAO/PHA,GAO → CASTO Kinetic parameters

Kinetic rate limitation/inhibitions

|

| CASTO growth on PHA,PAO and PHA,GAO, NOx/NO2/NO3 |

PHA,PAO/PHA,GAO → CASTO Kinetic parameters

Kinetic rate limitation/inhibitions

|

| PAO polyphosphate storage, O2 |

SPO4 → XPP Kinetic parameters

Kinetic rate limitation/inhibitions

|

| PAO polyphosphate storage, NOx/NO2/NO3 |

SPO4 → XPP Kinetic parameters

Kinetic rate limitation/inhibitions

|

| PAO growth on PHA,PAO, O2; PO4 limited |

PHA,PAO → CASTO Kinetic parameters

Kinetic rate limitation/inhibitions

|

| PAO growth on PHA,PAO, NOx/NO2/NO3; PO4 limited |

PHA,PAO → CASTO Kinetic parameters

Kinetic rate limitation/inhibitions

|

| PAO's PHA,PAO storage from VFAs and PO4 release |

VFA → PHA,PAO and XPP → SPO4 Kinetic parameters

Kinetic rate limitation/inhibitions

|

| GAO's PHA,GAO storage from VFAs |

VFA → PHA,GAO Kinetic parameters

Kinetic rate limitation/inhibitions

|

| CASTO aerobic maintenance |

PHA,PAO → CO2 and PHA,GAO → CO2 Requires O2. Kinetic parameters

Kinetic rate limitation/inhibitions

|

| CASTO anoxic maintenance, NOx/NO2/NO3 |

PHA,PAO → CO2 and PHA,GAO → CO2 Requires NOx/NO2/NO3. Kinetic parameters

Kinetic rate limitation/inhibitions

|

| GAO anaerobic maintenance |

PHA,GAO → VFA Kinetic parameters

Kinetic rate limitation/inhibitions

|

| PP cleavage for maintenance |

PP → PO4 Rate expression covers the aerobic, anoxic and anaerobic PP cleavage as follows (Sumo1, MODEL sheet, row 27, column CB): r24 = bPP,ana,T * XPAO * LogsatXPP,KPO4,PAO * (ηbPP,aer * MRinhXPHA,XPAO,KPHA,cle * MsatSO2,KO2,CASTO + ηbPP,anox * MinhSO2,KO2,CASTO * MsatSNOx,KNOx,CASTO + MinhSO2,KO2,CASTO * MinhSNOx,KNOx,CASTO) Kinetic parameters

Kinetic rate limitation/inhibitions

|

| SB fermentation with high VFA (PAO growth, anaerobic) |

SB → VFA + CASTO Kinetic parameters

Activity limitation

Kinetic rate limitation/inhibitions

|

| SB fermentation with low VFA (PAO growth, anaerobic) |

SB → VFA + CASTO Kinetic parameters

Activity limitation

Kinetic rate limitation/inhibitions

|

| CASTO decay |

CASTO → XB,e and XE under anoxic and aerobic conditions. Kinetic parameters

Kinetic rate limitation/inhibitions

|

| CASTO anaerobic decay |

CASTO → XB,e and XE under anaerobic conditions. Kinetic parameters

Kinetic rate limitation/inhibitions

|

¶ Chemical phosphorus removal

Phosphorus can be chemically removed by:

- metal salt addition (iron or aluminium). The chemical processes implemented in the model are described in a dedicated paragraph)

- natural or induced precipitation of:

- Amorphous calcium phosphate (Ca3(PO4)2 * 4H2O)

- Brushite (CaHPO4 * 2H2O)

- Struvite (MgNH4PO4 * 6H2O)

- Vivianite (Fe3(PO4)2 * 8H2O)

The chemical precipitation model is described in a dedicated paragraph.

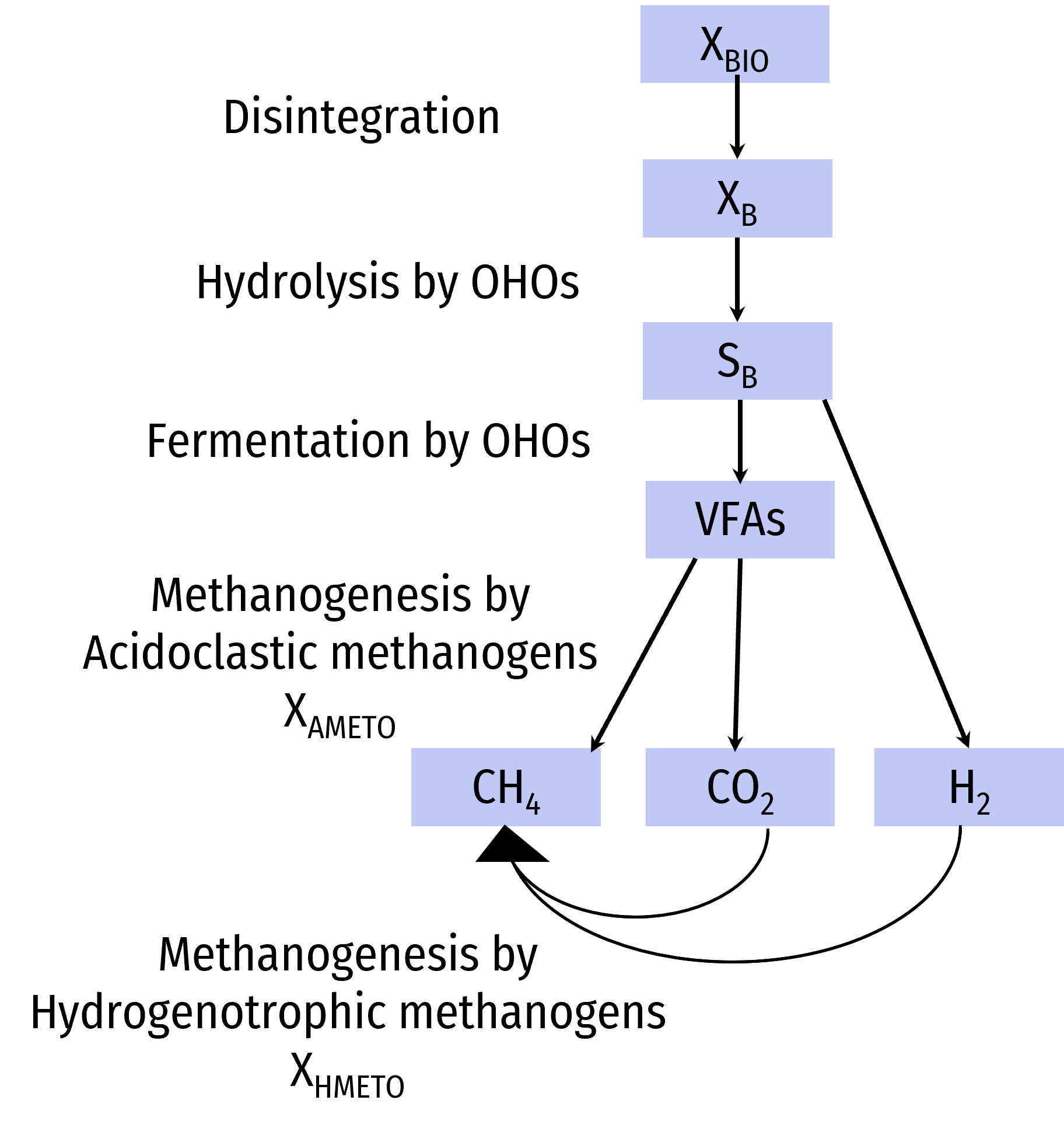

¶ Anaerobic digestion processes

All Sumo models describe the anaerobic digestion processes involving 3 biomasses: the OHOs with fermentation process, Acidoclastic methanogens (AMETOs) and hydrogenotrophic methanogens (HMETOs).

The typical pathway of anaerobic digestion is the lysis of all biomasses (except OHOs and methanogens), hydrolysis of biodegradable particulate substrate, fermentation and methanogenesis, leading to methane production.

The OHOs fermentation proces is described in BOD removal paragraph.

¶ Methanogenesis

¶ Acidoclastic methanogens, XAMETO

Anaerobic archea that consume SVFA to produce SCH4 and SCO2 as a metabolic by-product and don’t grow under aerobic conditions.

| Biological processes | Concepts description |

|---|---|

| AMETO growth |

Substrate is SVFA and produce SCH4. Too much SVFA results in a Haldane SVFA inhibition Free ammonia inhibition Requires nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH. |

| AMETO decay | AMETO decay process under anoxic and aerobic conditions. This process release XB,e and XE (death-regeneration concept). |

| AMETO anaerobic decay | AMETO decay process under anaerobic conditions. This process release XB,e and XE,ana (death-regeneration concept). |

¶ Hydrogenotrophic methanogens, XHMETO

Anaerobic archea that consume SH2 and SCO2 to produce SCH4 as a metabolic by-product and don’t grow under aerobic conditions.

| Biological processes | Concepts description |

|---|---|

| HMETO growth |

Substrate H2 and produce SCH4. Bell shape inhibition function on pH: BellinhpH. |

| HMETO decay | HMETO decay process under anoxic and aerobic conditions. This process release XB,e and XE (death-regeneration concept). |

| HMETO anaerobic decay | HMETO decay process under anaerobic conditions. This process release XB,e and XE,ana (death-regeneration concept). |

¶ Biological conversions

¶ Flocculation

Flocculation is a process where colloidal components in liquid phase are aggregated into larger flocs thus behave as particulates. In Sumo models flocculation process is a conversion of colloidal components into particulates. The process rate is depending on the concentration of total biomass.

The addition of metal salts (iron as HFO or alum as HAO) increase the flocculation rate of colloidal material, and can be used as a chemical addition for this purpose in primary settlers.

¶ Hydrolysis

Hydrolysis is a process where larger molecules are broken into smaller molecules which are soluble in liquid phase and available for bacterial growth with a certain delay (enzymatic processing, chemical dissolution, mass transport, storage, etc.).

Depending on the origin of the organic molecules, two types of hydrolysis reactions can be distinguished: hydrolysis of ‘‘primary substrate’’ that comes from the influent and hydrolysis of the matter produced by biomass metabolism or decay, named ‘‘secondary substrate,’’ in which protozoa may play an important role (Morgenroth et al., 2002). Consequently, models using the death-regeneration concept to model biomass decay, as Sumo models, merge those two types of hydrolysis in a single process, whereas in case of the endogenous respiration concept, the hydrolysis of secondary substrate is modeled through endogenous respiration and maintenance processes.

Several authors have implemented parallel hydrolysis of particulate organics with different hydrolysis rate (Ohron et al, 1998; Larrea et al., 2002). Anaerobic digestion modeling of different proportions of primary and secondary sludge in the feed have been proved to be better simulated with two particulate substrates: one particulate substrate from influent with higher hydrolysis rate, and one particulate substrate from biomass decay with a lower hydrolysis rate.

In Sumo hydrolysis is a biological process where particulate components are converted into soluble components. Two particulate substrates are distinguished:

- XB coming with the influent (primary substrate)

- XB,e coming from the biomass decay (secondary substrate)

The process rate is higher for XB (3 d-1) than for XB,e (1 d-1) and depend on the concentration of heterotroph biomass.

Larrea, L., Irizar, I., Hildago, M.E., 2002. Improving the predictions of ASM2d through modelling in practice. Water Sci. Technol. 45, 199–208.

Morgenroth, E., Kommedal, R., Harremoes, P., 2002. Processes and modeling of hydrolysis of particulate organic matter in aerobic wastewater treatment - A review. Water Sci. Technol. 45, 25–40.

Orhon, D., Cokgor, E.U., Sozen, S., 1998. Dual hydrolysis model of the slowly biodegradable substrate in activated sludge systems. Biotechnol. Tech. 12, 737–741.

Ozyildiz, G., Zengin, G.E., Güven, D., Cokgor, E., Özdemir, Ö., Hauduc, H., Takács, I., Insel, G., 2023. Restructuring anaerobic hydrolysis kinetics in plant-wide models for accurate prediction of biogas production. Water Res. 245, 120620. https://doi.org/1ce0.1016/j.watres.2023.120620

¶ Ammonification

The ammonification process is part of the nitrogen cycle when organic nitrogen is turned into soluble ammonia. In Sumo models soluble organic nitrogen compound is converted into ammonia. The process rate is depending on the concentration of heterotroph biomass.

¶ Biological phosphorus conversion

Biological phosphorus conversion is similar to the ammonification process but in this process organic phosphorus is converted into phosphate. The process rate is depending on the concentration of heterotroph biomass.

¶ Endogenous products conversion

In Sumo model this process is used to mimic the extreme slow hydrolysis of endogenous decay products by slowly converting XE to particulate biodegradable substrate. The process rate is depending on the concentration of heterotroph biomass.

¶ Anaerobic methanol conversion

Fermentation process of methanol utilizer organisms under anaerobic condition. The process rate depends on the methanol utilizer organisms concentration.

¶ Nitrate/Nitrite assimilative reduction

Processes that occur only under limited ammonia availability. It ensures sufficient ammonia production for biomasses growth by reducing SNO3 and SNO2 into SNHx with the biomasses as electron donors.

¶ Photosynthesis processes

Photosynthetic processes are active only in the Gen3 pond process unit. The photosynthetic organisms (XALGAE) are considered as one biomass group which can grow, respire and decay.

Growth is dependent on the user input "Solar radiation for algal photosynthesis - depth averaged" which may vary depending on time of day (there is no sunlight at night), latitude and season, cloud cover as well as the depth of the pond. It is the user's responsibility to account for these factors when specifying the depth averaged solar radiation. Specifying diurnal and seasonal variations of solar radiation is possible using Input Dynamics.

The effect of shading in the water column due to influent particulate material, as well as algae itself, is accounted for using the parameter "TSS concentration for calculating light extinction switching factor". When the simulated TSS concentration in the water column approaches this value, the growth rate of algae switches to zero regardless of what the specified value is for "Solar radiation for algal photosynthesis - depth averaged".

Growth of algae is accompanied by assimilation of ammonia as a nutrient source unless ammonia becomes limiting in which case nitrate is assimilated. Phosphorus and carbon dioxide are also assimilated for growth.

Respiration of algae is simulated when oxygen is available. Respiration means the conversion of algae into water, CO2, ammonia and phosphate by oxydation using oxygen. In the absence of oxygen, the respiration rate switches to zero and decay of algae is switched on. Decay means the lysis of algae into particulate organic material, ammonia and phosphate and occurs in the pond sediments where oxygen is absent.

¶ Mechanisms of focus models

The chapter describes in details the model mechanisms and refers to publications.

¶ Sumo2C

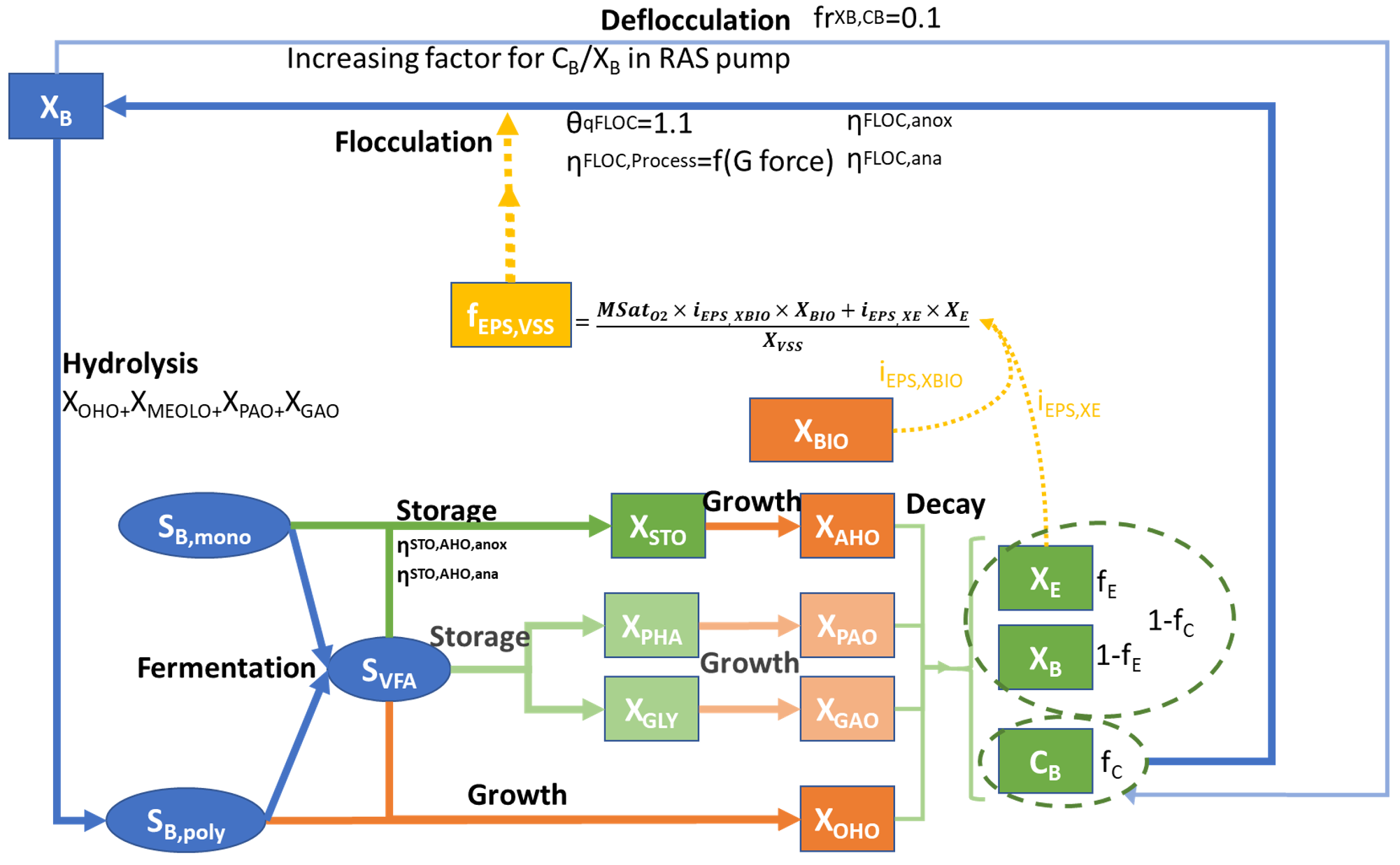

The whole-plant model SUMO2 (Dynamita, 2016, described in previous chapter) considering typical biological and physio-chemical model was modified to include the required components and processes in accordance with the critical review of existing models and experimental data, as summarized in Sumo2C Figure 1:

- Readily biodegradable substrate (SB) is split into monomers and polymers (SB,mono and SB,poly).

- A new biomass, A-Stage Heterotrophic Organisms (AHO) is added. This biomass stores SB,mono and SVFA into XSTO and has a high growth rate, while the Ordinary Heterotrophic Organisms consume only SB,poly and have a reduced growth rate.

- Hydrolysis process is performed only by low growth rate heterotrophic organisms (OHO, MEOLO, PAO and GAO) to simulate the low hydrolysis observed in A-Stage processes.

- Decay processes produce a fraction (fC) of colloids, split into biodegradable and unbiodegradable colloids (CB and CU) in the same fE proportion, as XE (particulate endogenous decay products) and XB,e (slowly biodegradable substrate) are generated in death-regeneration models.

- The modified model incorporates modeled EPS (XMEPS) as a flocculation agent, calculated variable based on a weighted sum of biomasses (XBIO) and particulate endogenous decay products (XE) related to the particulate COD (XCOD), with a saturation function on oxygen, meaning that under low DO, EPS are less produced (Nogaj et al., 2015). The calculated XMEPS is an indicator of EPS production, but the calculated values results depending on the analysis method used by different authors.

- The kinetic rate of flocculation processes are first order reactions that depend on the calculated XMEPS concentration. The rate is reduced under anoxic and anaerobic conditions to match with experimental observations. Furthermore, the flocculation rate is sensitive to temperature and to mixing intensity, represented in the model with a flocculation factor (Ff in %) that can be vary in each reactor depending on the aeration and mixing technology (Ff=0.1 for mechanical mixing, 0.5 for coarse bubbles, 0.75 for anaerobic processes).

- An empirical pump process unit is implemented to simulate the deflocculation processes occurring at pumping. The factor for the increase in CB/XB and CU/XU ratio can be adjusted depending on the pump technology.

¶ Carbon absorption heterotroph organisms, XAHO

Heterotrophic organisms storing readily biodegradable small molecular weight components represented as SB,mono and volatile fatty acids (SVFA) into XSTO. The growth rate of AHOs is higher than that of the OHOs and outgrow them in a short SRT system of <2 days. They only carry out aerobic consumption of the XSTO and are expected to be seeded from the influent.

| Biological processes | Concepts description |

|---|---|

| AHO storage of SB,mono | Storage of SB,mono into XSTO without any energy required |

| AHO storage of SVFA | Storage of SVFA into XSTO without any energy required |

| AHO growth on XSTO, O2 | Requires O2, XSTO and nutrients. This is the AHO growth process. |

| AHO decay | Decay process of AHO under anoxic and aerobic conditions, resulting in XB,e, CB and XE release. XSTO is also considered to be released in the proportion of XSTO/XAHO. |

| AHO anaerobic decay | Decay process of AHO under anaerobic conditions, resulting in XB,e, CB and XE,ana release. XSTO is also considered to be released in the proportion of XSTO/XAHO. |

Haider, S., Svardal, K., Vanrolleghem, P.A., Kroiss, H., 2003. The effect of low sludge age on wastewater fractionation (S(S), S(I)). Water Sci. Technol. J. Int. Assoc. Water Pollut. Res. 47, 203–209.

Nogaj, T., Randall, A., Jimenez, J., Takacs, I., Bott, C., Miller, M., Murthy, S., Wett, B., 2015. Modeling of organic substrate transformation in the high-rate activated sludge process. Water Sci. Technol. 71, 971–979. https://doi.org/10.2166/wst.2015.051

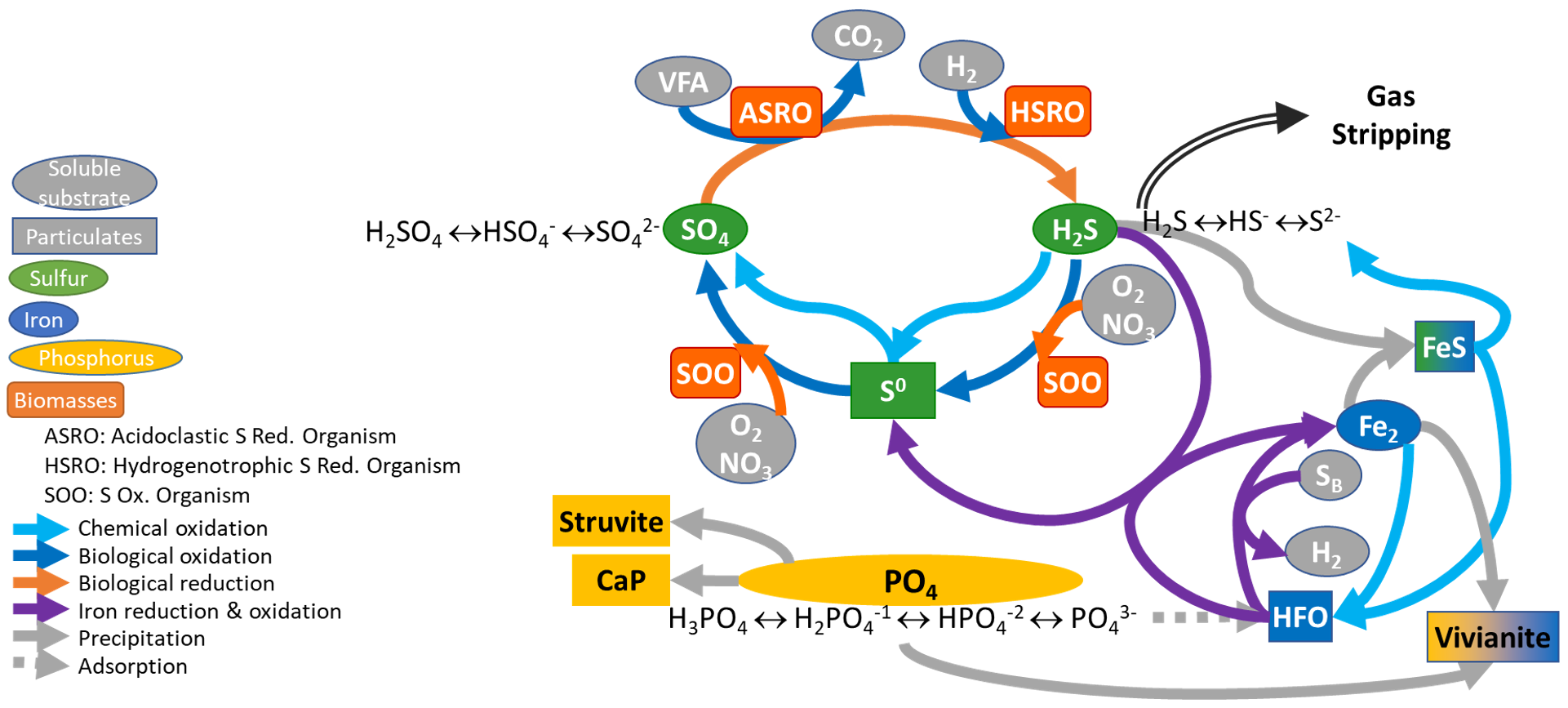

¶ Sumo2S

Biology and chemistry was extended with required components, species and reactions in accordance to the following literature review. Sumo2S Figure 1 synthesizes the sulfur cycle implemented in Sumo© models (Dynamita 2018) and the interactions with phosphorus and iron cycles.

¶ General sulfur and iron model

The sulfur model included in Sumo includes three oxidation states of sulfur: Sulfate (SO4-2) as SSO4, elemental sulfur (S0) as XS, and sulfide (S-) as SH2S.

Considering iron, two oxidation states are included in the model. Hydrous ferric oxides (HFO) species are already included in the base model for the chemical phosphorus treatment. These state variables (XHFO,H, XHFO,L, XHFO,old, XHFO,H,P, XHFO,L,P, XHFO,H,P,old and XHFO,L,P,old depending on the floc size and P-bound status) are considered to be the only ferric (Fe3+) species in the model, as ferric iron is only minimally soluble in water (Hauduc et al., 2015). XHFO is a calculated variable being the sum of the seven HFO state variables. For the ferrous iron (Fe2+), a new state variable is included in the model as SFe2, and ferrous oxides are not considered.

These states are considered to interact with other wastewater components as described below.

¶ FeS precipitation and iron interaction

¶ Reduction of Fe3+, sulfide as electron donor

A chemical reduction of Fe3+ by sulfide occurs under reducing conditions. In this reaction, sulfide is oxidized into colloidal elemental sulfur which precipitates (Firer et al., 2008; Nielsen et al., 2005):

2 Fe3+ + HS- → 2 Fe2+ + S0 + H+

Implementation in the whole plant model: Elemental sulfur has been added as a particulate state variable (XS), as elemental sulfur has a low solubility and flocculates easily. The hydrous ferric oxides (XHFO) are reduced by H2S in a single process into ferrous iron (SFe2) and elemental sulfur (XS) with adequate stoichiometric coefficient to balance the redox reaction and a first order rate with respect to the XHFO concentration.

¶ Reduction of Fe3+, organic matter as electron donor

Hydrous ferric oxides are reduced in digesters into soluble Fe2+ which precipitates into iron sulfide [FeS], and release bounded phosphates (Ge et al., 2013), that can further precipitate into vivianite [Fe3(PO4)2,8H2O] (Cheng et al., 2015). This biological process is performed by Fe3+ reducing bacteria, using organic matter as electron donors (Lovley and Phillips, 1988).

Implementation in the whole plant model: To keep the model simple, this new iron reducing biomass and the associated growth is not introduced in the model. The soluble biodegradable substrate (SB) and volatile acids (SVFA) are considered as electron donor and a first order kinetic rate expression with respect to the hydrous ferric oxide (XHFO) concentration is used.

¶ FeS precipitation

Fe2+ precipitates with sulfide into iron sulfide, FeS (Firer et al., 2008; Nielsen et al., 2005):

Fe2+ + HS- → FeS + H+

Implementation in the whole plant model: The acid-base reactions of the sulfate and sulfide species are added in the pH model for speciation (equilibrium model). The precipitation is modelled following Koutsoukos et al (1980) kinetic expression with a solubility product Ksp,FeS=3.7*10-19 (Nielsen et al., 2005).

¶ Oxidation of Fe2+

According to Gutierrez et al. (2010), the precipitated iron sulfide (FeS) is re-oxidized into ferric oxides and sulfate in an aerobic zone.

Implementation in the whole plant model: Both oxidation of ferrous iron (SFe2) and precipitated iron sulfide (XFeS) are considered in the model with oxygen as electron acceptor with adequate stoichiometric coefficient to balance the redox reaction and a first order rate with respect to the SFe2 and XFeS concentrations respectively.

¶ Reduction of sulfate

The biological sulfate reduction is the main process step in sulfur biotreatment, often combined with a chemical step or a metal precipitation step (Hao et al., 2014). The biological sulfate reduction is performed by sulfate reducing organisms (SRO), which can use either hydrogen or organic compounds as electron donor. These bacteria are directly in competition with hydrogenotrophic and acetoclastic methanogens respectively in anaerobic bioprocesses (Chou et al., 2008; Hao et al., 2014; Kalyuzhnyi and Fedorovich, 1998) and in sewer sediments (Liu et al., 2016). Models for sewer system usually neglect the biomass growth whereas models for anaerobic digestion always consider it. These models consider different kind of substrates. Knobel and Lewis (2002), Liu et al. (2015) and Fedorovich et al. (2003) consider 5 or 4 substrates respectively (different volatile fatty acids and H2), whereas Batstone (2006) suggests considering only hydrogenotrophic sulfate reducer bacteria if S/COD ratio is below 0.1 mg S/mg COD. The best compromise seems to be the model from Barrera et al. (2015) and Poinapen and Ekama (2010) who consider H2, acetate and propionate as substrates. The WATS model for sewer processes (Hvitved-Jacobsen et al., 2013) consider only soluble substrate for sulfate reduction biological processes.

Implementation in the whole plant model: Considering the actual structure of the extended version of Sumo model, SVFA and SH2 have been chosen as substrate for sulfate reducing organisms (SRO), resulting in competition with the AMETO and HMETO, which would be similar to what is suggested by Barrera (2015) and in accordance with Kalyuzhnyi and Federovich (1998). Similarly to the methanogenesis implementation, two biomasses are introduced: ASRO (Acidoclastic Sulfate-Reducing Organisms) and HSRO (Hydrogenotrophic Sulfate-Reducing Organisms). This leads to 4 additional processes to consider growth and decay of both biomasses. Stoichiometric and kinetic values from Barrera (2015) are used. The produced sulfide is inhibitory (Utgikar et al. 2002). It has been considered in the kinetic rate expression through Haldane functions when sulfide is a reactant of the process, otherwise through Monod limitation function term.

¶ Oxidation of sulfide

¶ Biological oxidation

The biological oxidation of sulfide into sulfate is performed through intermediate species. The oxidation may use either oxygen, nitrite or nitrate as electron acceptor. In the literature, the biological oxidation of sulfide is mainly modelled in one or two steps, elemental sulfur (S0) being the intermediate. The oxidation of elemental sulfur to sulfate is the limiting step (Buisman, et al., 1991; Jiang et al., 2009; Tichy et al., 1998). According to several authors, when sulfide is oxidized in a digester at limited oxygen levels, it reacts to elemental sulfur which precipitates, making it less available for further biological reduction (Diaz and Fdz-Polanco 2012; Jenicek et al. 2008).

Implementation in the whole plant model: A Sulfur Oxidizing Organism (XSOO) has been introduced in the model with four oxidation processes to consider the two steps of sulfide oxidation and two possible oxidants (O2 and NO3). The parameter values from Mannucci et al (2012) are used as first estimation.

¶ Chemical oxidation

At high SOO activity, chemical oxidation is negligible (Luther et al., 2011) but must be considered in case of sewer processes with lower biomass concentration as the oxygen consumption for sulfide oxidation count significantly in the OUR (Nielsen et al., 2003). The literature reports kinetic laws with different orders and a wide range of oxidation rate parameters, however the rate of the two steps of oxidation are not determined independently (Buisman et al., 1990; Hvitved-Jacobsen et al., 2013; Klok et al., 2013; Luther et al., 2011; Nielsen et al., 2003).

Implementation in the whole plant model: Two processes for oxidation of SH2S by oxygen in two steps (SH2S→XS→SSO4) is added. All the oxidation intermediates are considered through the elemental sulfur state variable (XS), whereas the second oxidation step (XS→SSO4) is much slower (Nielsen et al., 2003). To simplify the model, first order reactions with respect to sulfide and to elemental sulfur has been implemented for both steps of the oxidation process.

¶ Biomasses involved in sulfur reactions

¶ Acidoclastic sulfate-reducing organisms, XASRO

A group of bacteria and archaea that perform anaerobic respiration utilizing SSO4 and SVFA, reducing it to SH2S and generating SCO2. They compete with AMETOs for SVFA and negatively impact performance of a digester.

| Biological processes | Concepts description |

|---|---|

| ASRO growth - SO4 reduction with SVFA |

ASRO growth process on SVFA, using SSO4 as electron acceptor. SH2S is produced. Requires SSO4 and nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH. |

| ASRO decay | ASRO decay process under anoxic and aerobic conditions. This process release XB,e and XE (death-regeneration concept). |

| ASRO anaerobic decay | ASRO decay process under anaerobic conditions. This process release XB,e and XE,ana (death-regeneration concept). |

¶ Hydrogenotrophic sulfate-reducing organisms, XHSRO

A group of bacteria and archaea that perform anaerobic respiration utilizing SSO4 and SH2, reducing it to SH2S. They compete with HMETOs for SH2 consumption and negatively impact performance of a digester.

| Biological processes | Concepts description |

|---|---|

| HSRO growth - SO4 reduction with SH2 |

HSRO growth process on SH2, using SSO4 as electron acceptor. SH2S is produced. Requires SSO4 and nutrients (SNHx, SPO4, SCAT, SAN, SCa, SMg). Bell shape inhibition function on pH: BellinhpH. |

| HSRO decay | HSRO decay process under anoxic and aerobic conditions. This process release XB,e and XE (death-regeneration concept). |

| HSRO anaerobic decay | HSRO decay process under anaerobic conditions. This process release XB,e and XE,ana (death-regeneration concept). |

¶ Sulfur-oxidizing organisms, XSOO

Sulfur-oxidizing organisms (SOO) oxidize SH2S in two steps under aerobic and anoxic environments, first from SH2S to XS (elemental sulfur) and second from XS to SSO4.

| Biological processes | Concepts description |

|---|---|

| SOO growth on H2S, O2 |

SOO aerobic growth, using SH2S as electron donor. SH2S is oxidised into elemental sulfur XS with SO2 as electron acceptor. Requires SH2S, SO2 and nutrients (SH2S, SNHx, SPO4, SCAT, SAN, SCa, SMg). |

| SOO growth on H2S, NO2 |

SOO anoxic growth, using SH2S as electron donor. SH2S is oxidised into elemental sulfur XS with SNO2 as electron acceptor. Requires SH2S, SNO2 and nutrients (SH2S, SNHx, SPO4, SCAT, SAN, SCa, SMg). |

| SOO growth on H2S, NO3 |

SOO anoxic growth, using SH2S as electron donor. SH2S is oxidised into elemental sulfur XS with SNO2 as electron acceptor. Requires SH2S, SNO2 and nutrients (SH2S, SNHx, SPO4, SCAT, SAN, SCa, SMg). |

| SOO growth on S°, O2 |

SOO aerobic growth, using elemental sulfur XS as electron donor. XS is oxidised into sulfate SSO4 with SO2 as electron acceptor. Requires XS, SO2 and nutrients (SH2S, SNHx, SPO4, SCAT, SAN, SCa, SMg). |

| SOO growth on S°, NO2 |

SOO anoxic growth, using elemental sulfur XS as electron donor. XS is oxidised into sulfate SSO4 with SNO2 as electron acceptor. Requires XS, SNO2 and nutrients (SH2S, SNHx, SPO4, SCAT, SAN, SCa, SMg). |

| SOO growth on S°, NO3 |

SOO anoxic growth, using elemental sulfur XS as electron donor. XS is oxidised into sulfate SSO4 with SNO3 as electron acceptor. Requires XS, SNO3 and nutrients (SH2S, SNHx, SPO4, SCAT, SAN, SCa, SMg). |

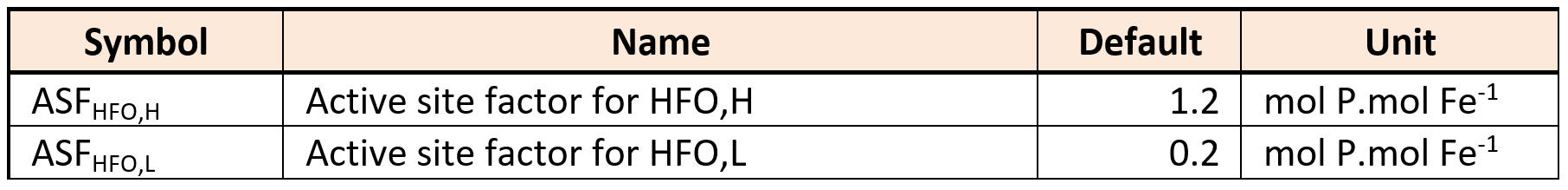

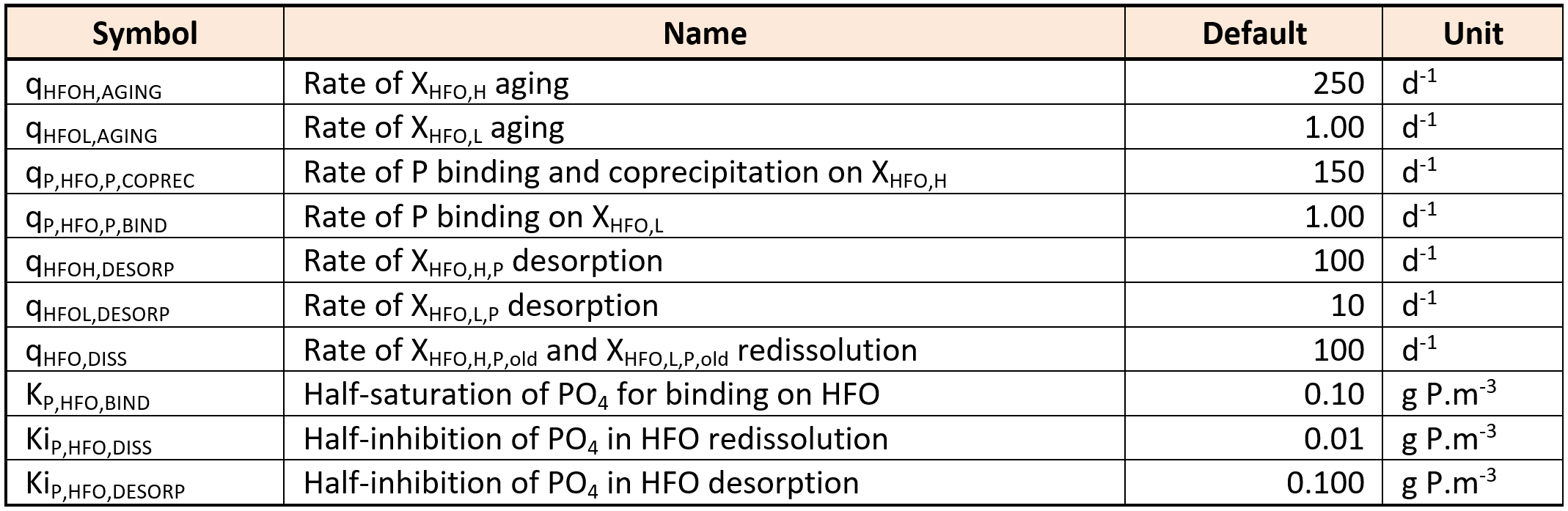

| SOO decay | SOO decay process under anoxic and aerobic conditions. This process release XB,e and XE (death-regeneration concept). |