¶ Overview

SUMO can be used for plant design as well, based on simple algebraic calculations. This version includes a design tool for AS plants that calculates the required reactor volume based on design SRT and MLSS.

To set up a plant design example, please follow the steps described below.

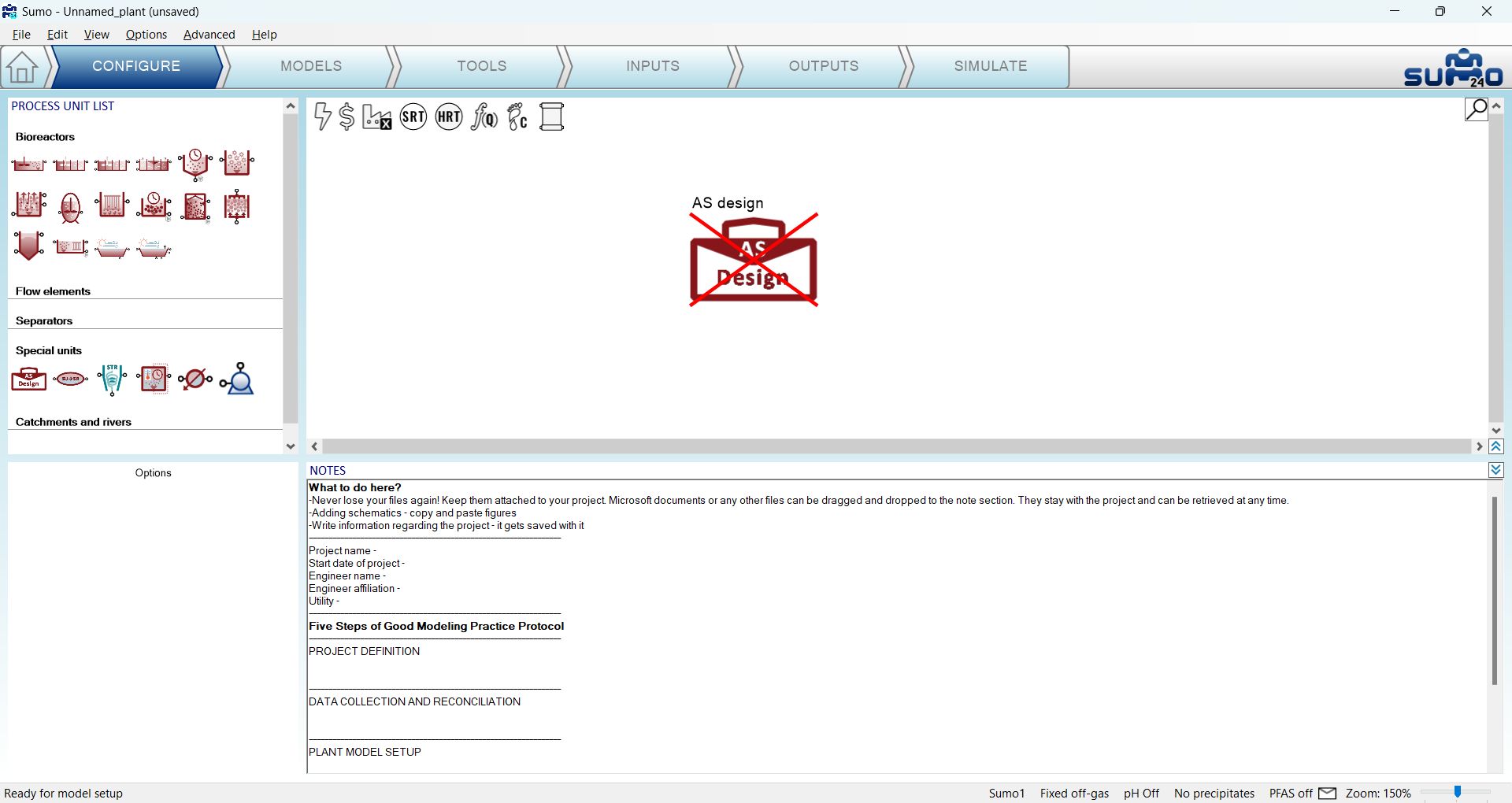

¶ Configure

Just like with dynamic configurations, to start the project, the relevant process unit has to be chosen on the Configure tab. For the current exercise, this will be the AS design from the Special units group. This unit is restricted to be only available for the design model. As the selection of the latter will take place in the model setup, at this point the unit will be indicated as invalid, crossed out with red lines (Figure 7.1.1).

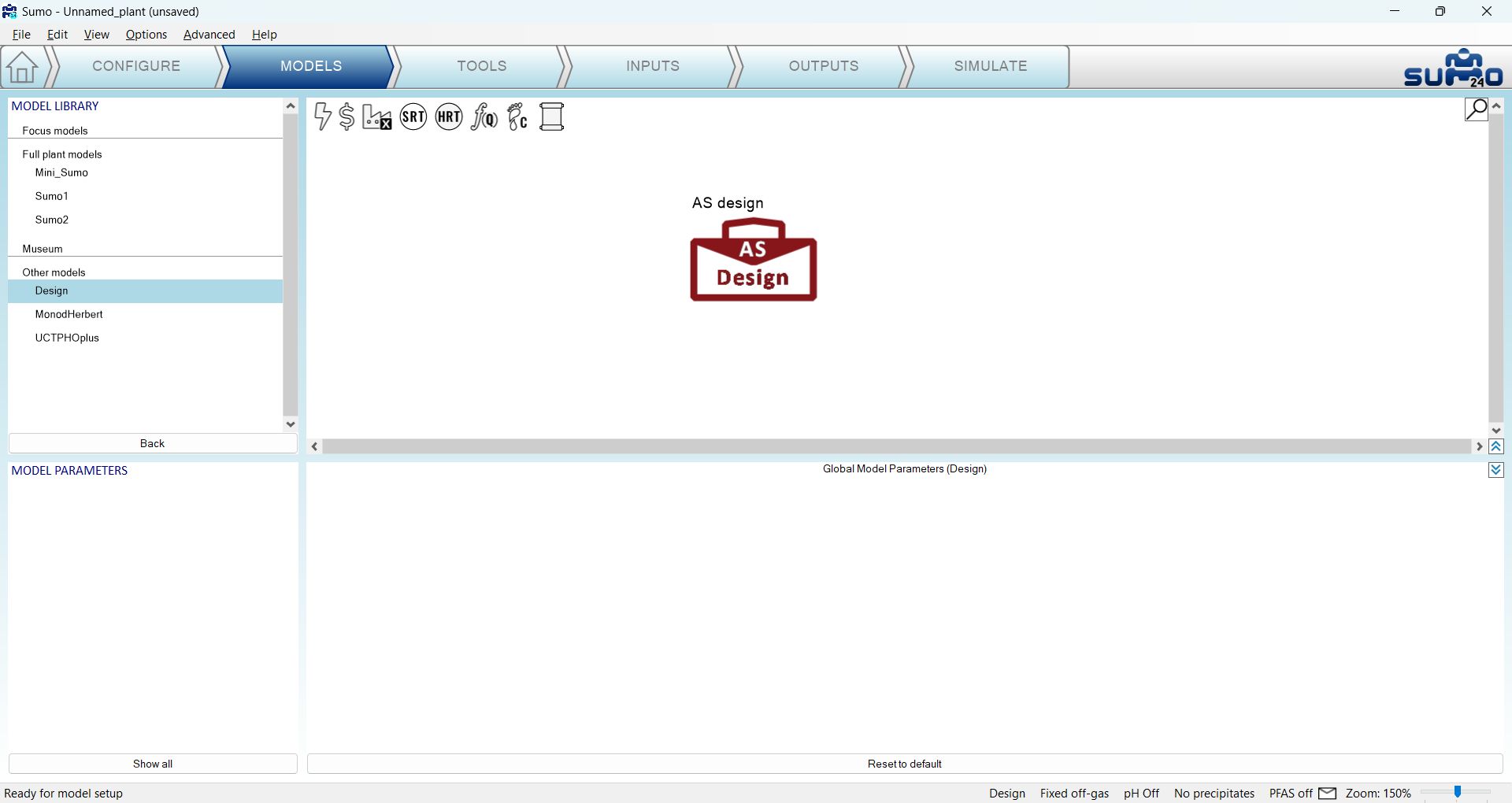

¶ Models

On the Models tab, please choose the Design model on the top left panel, which is available under Model selection/Museum, focus and custom models/Other models/Design. The process unit will become indicated as valid (Figure 7.1.2).

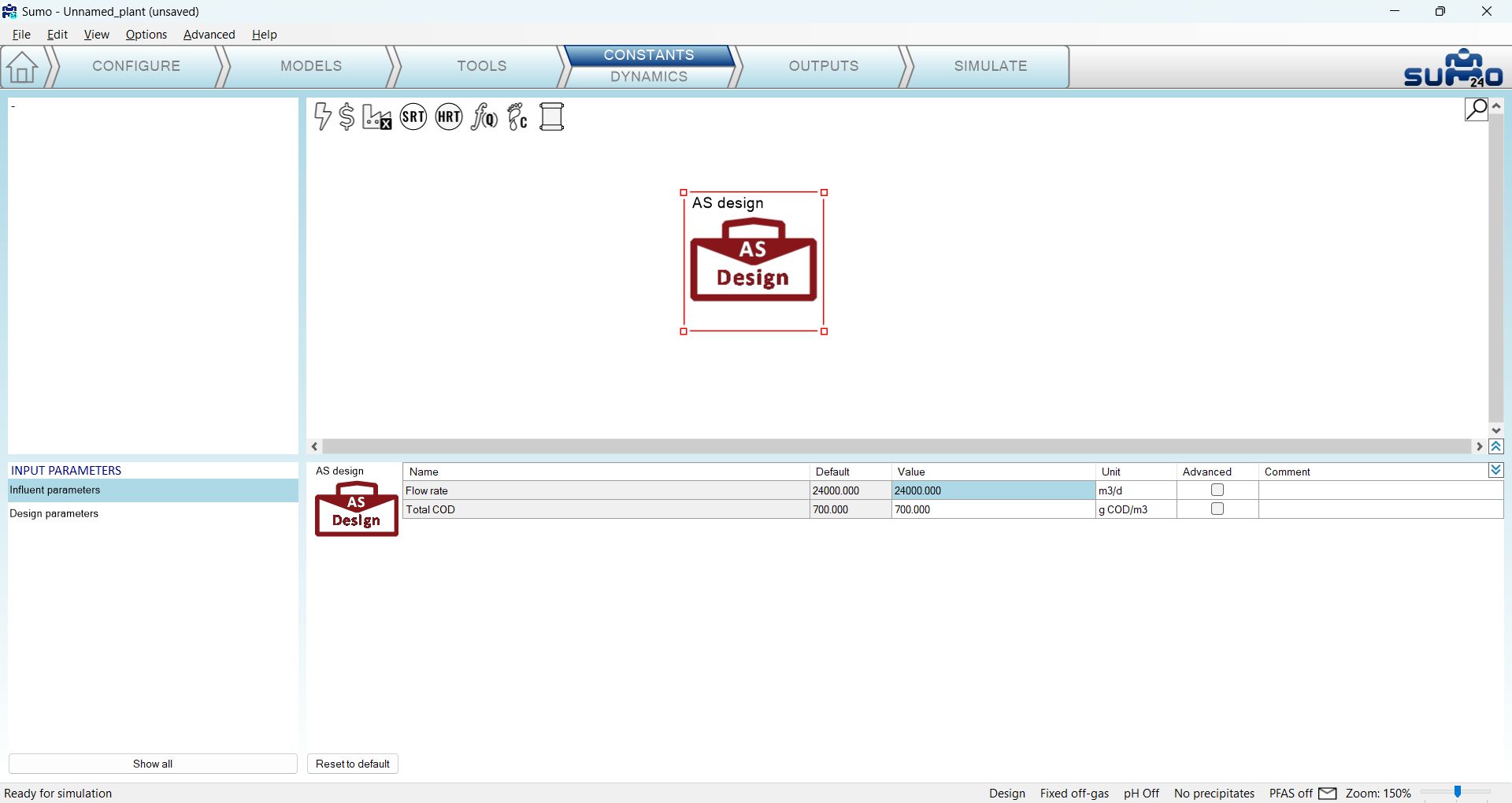

¶ Inputs

On the Inputs tab, the main influent and design parameters can be set (Figure 7.1.3). By clicking on the Show all button, further details (such as COD and biomass fractions) can be added.

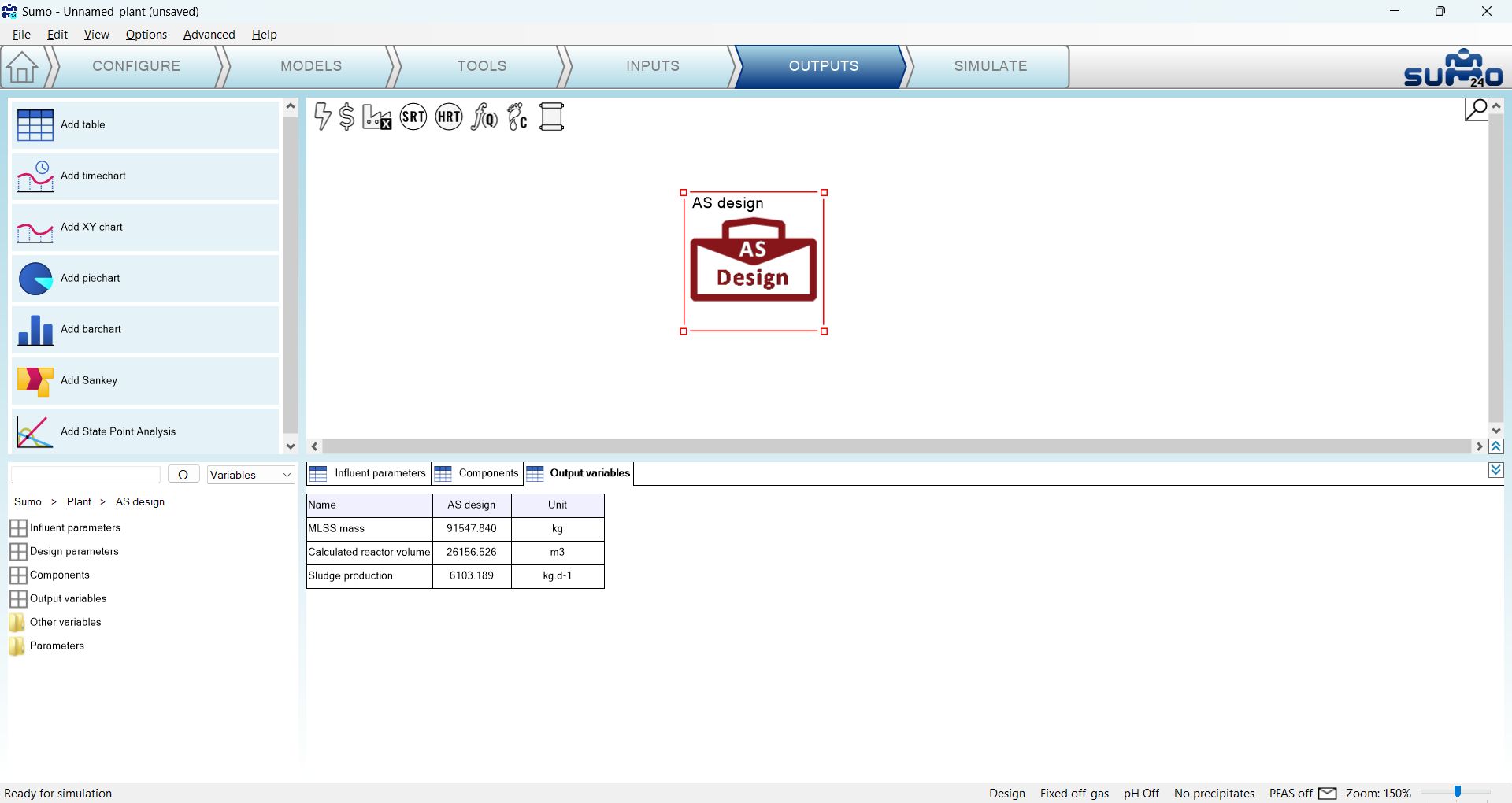

¶ Outputs

Tables can be added here, similarly to the dynamic configurations (Figure 7.1.4).

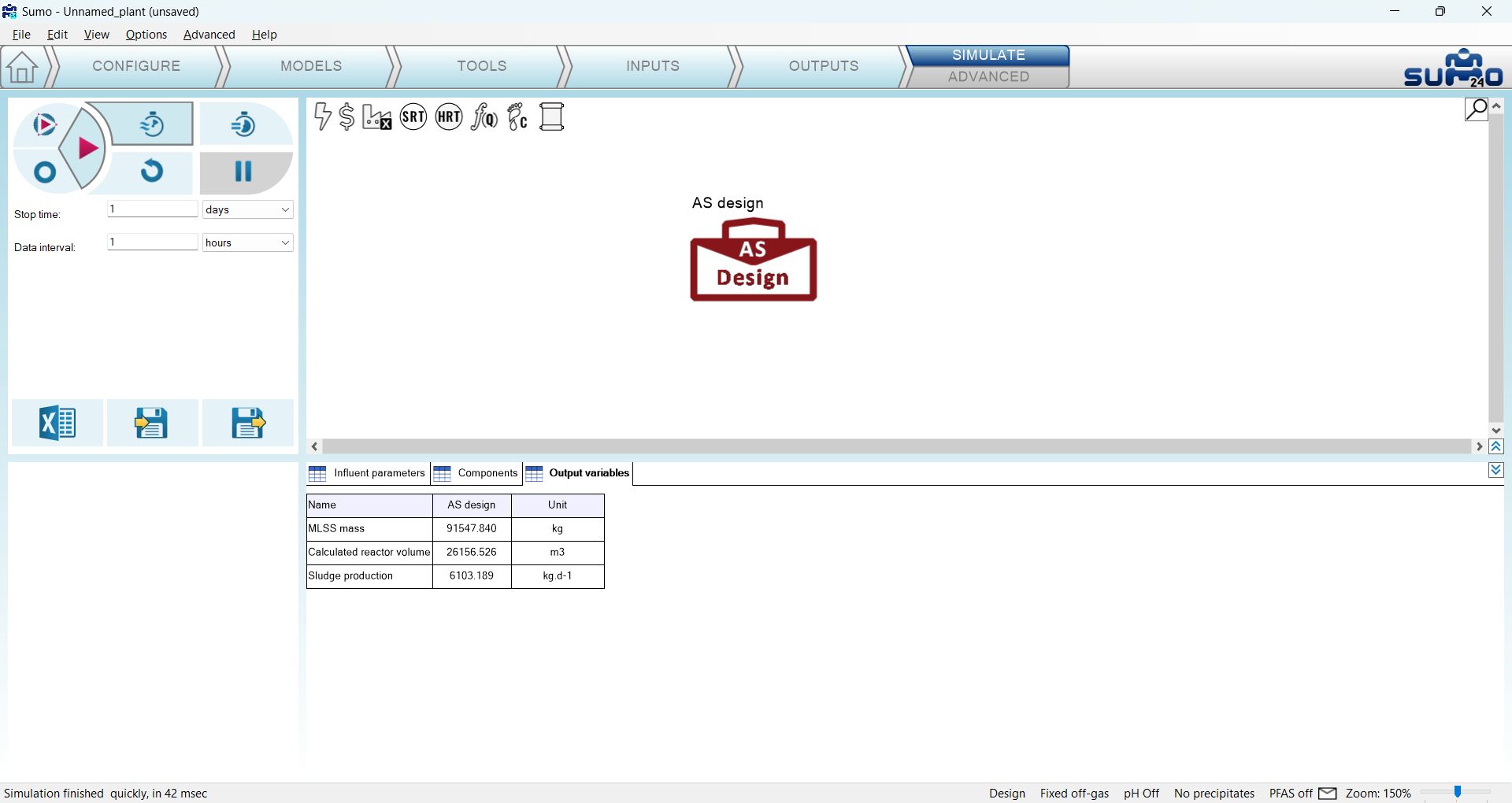

¶ Simulate

On the Simulate tab, click any of the three simulation start buttons (as the underlying calculations are algebraic, it does not matter which simulation mode is chosen) and the desired calculations will be executed (Figure 7.1.5). A report of the results can be exported in Excel format by clicking on the Report icon below the simulation control panel.

¶ Next chapter

Chapter 8 – Examples